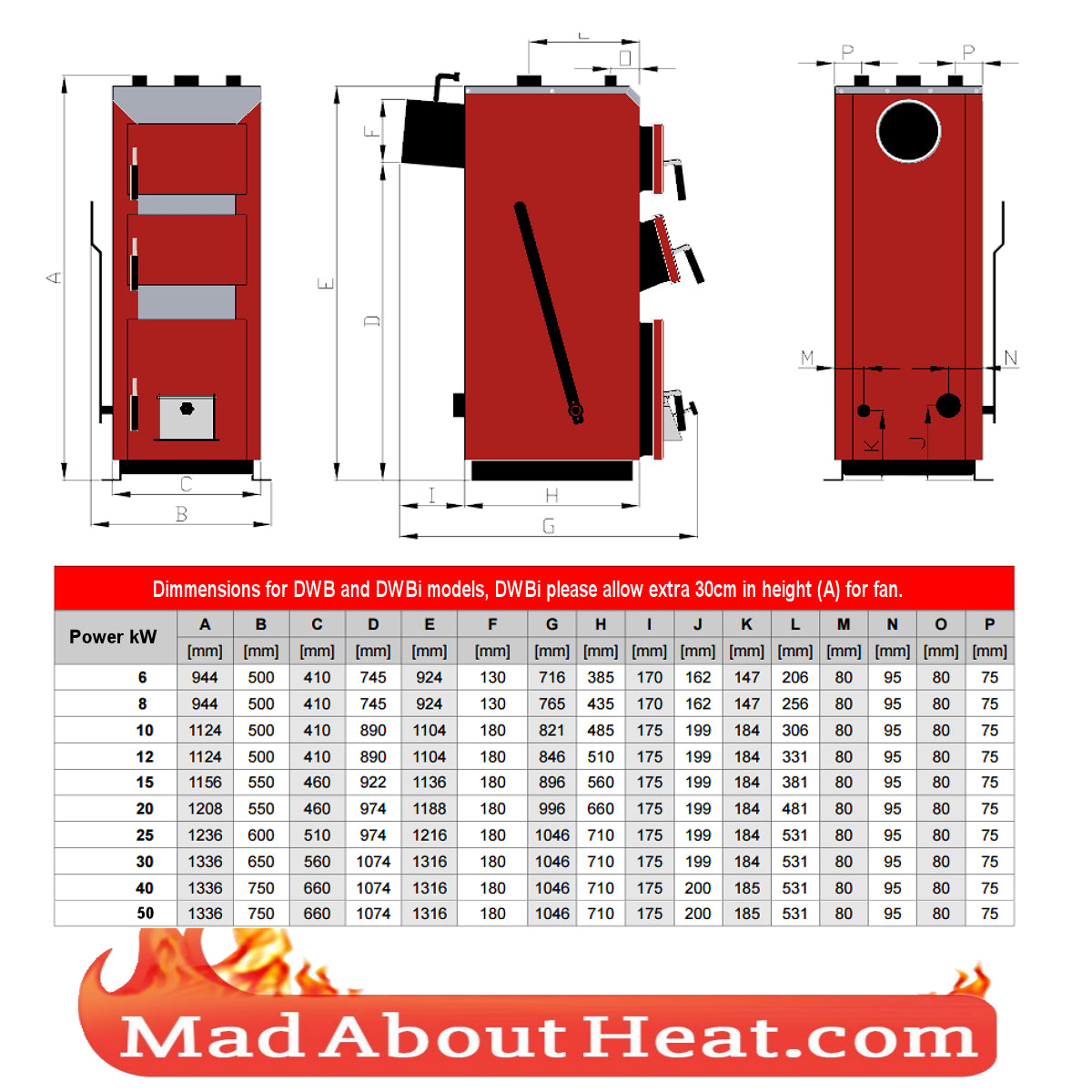

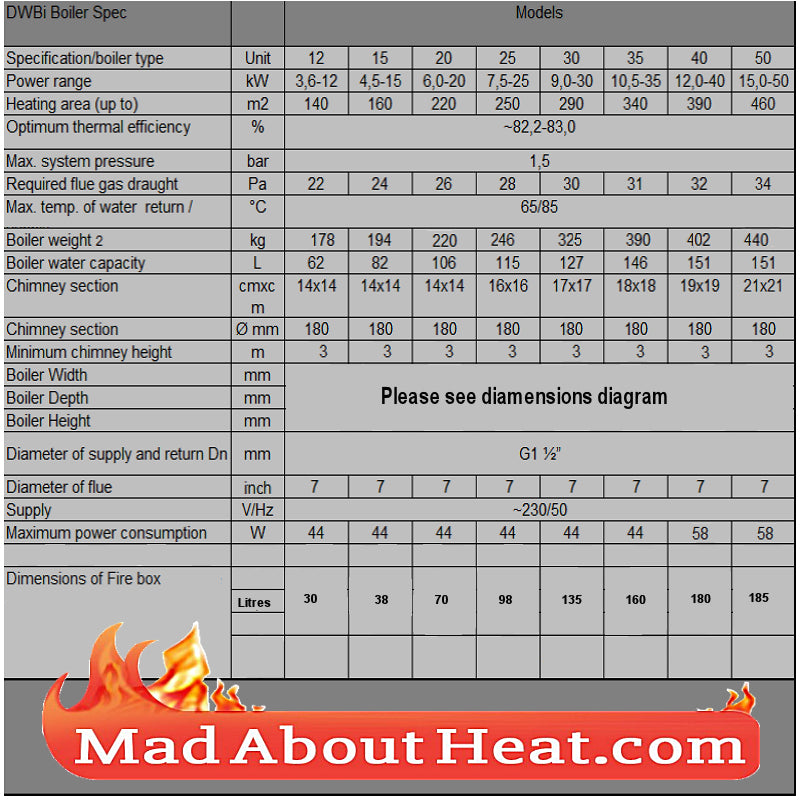

DWBi Fan Assisted, Semi Automatic, Biomass Wood And Coal Boilers

DWBi Fan Assisted, Semi Automatic, Biomass Wood And Coal Boilers - DWBi 12kW is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

These items are bulky and require delivery on a pallet, please contact us to arrange.

Solid well made design.

Description

Description

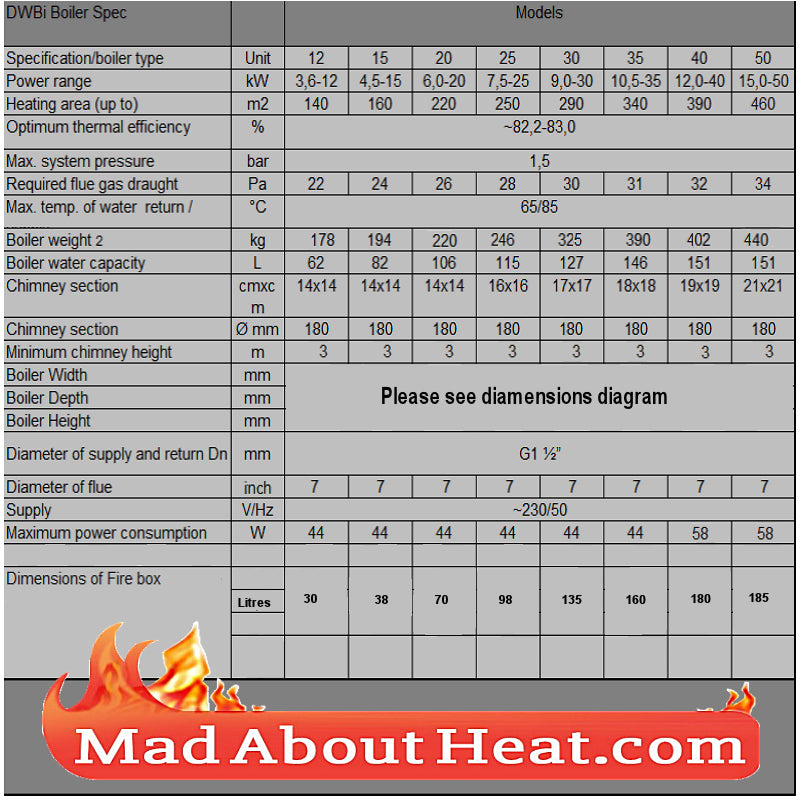

DWBi Multi fuel fan assisted wood, coal, cardboard, burn wood waste boiler.

Central Heating & Hot Water Solid Fuel Boiler.

DWBi line of multi fuel wood boilers characterized by a simple, aesthetic and solid construction with added fan assistance and temperature control. Giving the burner ability to produce heat for central heating and consumable hot water from burning just about anything flammable.

Originally made for us in 2006, the DWB and DWBi boilers have evolved to meet requirements of our customers.

These following requirement kept being mentioned;

1. Ability to burn wide variety of fuels.

DWB and DWBi can burn just about anything, from coal and wood through cardboard, plywood, mdf, chipboard to grain, straw and kitchen waste (where legally permissible).

DWBi additional computer controlled fan assistance gives the burner incinerator like characteristics.

2. Simple in design and operation.

Many of us used or still use an open fire or a stove and have experienced of what is involved performing this task. The DWBi boiler is not that different. Filling the boiler through middle door, initially lighting the fire at the top, close the door and adjust the draft or fan speed to suit. Once boiler water temperature is reached the fan cuts off air supply thus starving fire of oxygen.

DWBi burn classification is a Hybrid between, firstly with the fan assistance boiler behaves like a high powered incinerator, or in manual mode where it can be used as a gasification type burner.

3. Solid build and made to last.

Both DWB and DWBi share the same chassis and physical dimension, they are both made for 5-6mm purpose made steel, made to resist heat stretch cracks and corrosion from acidic fuels. From the moment we hold the handle and open the door, the solid well made design is instantly felt. Weld joints are on the water jacket side and kept to minimum with folding carried out through majority of the boiler. Realistic life expectancy is 20+ years.

4. High burn efficiency.

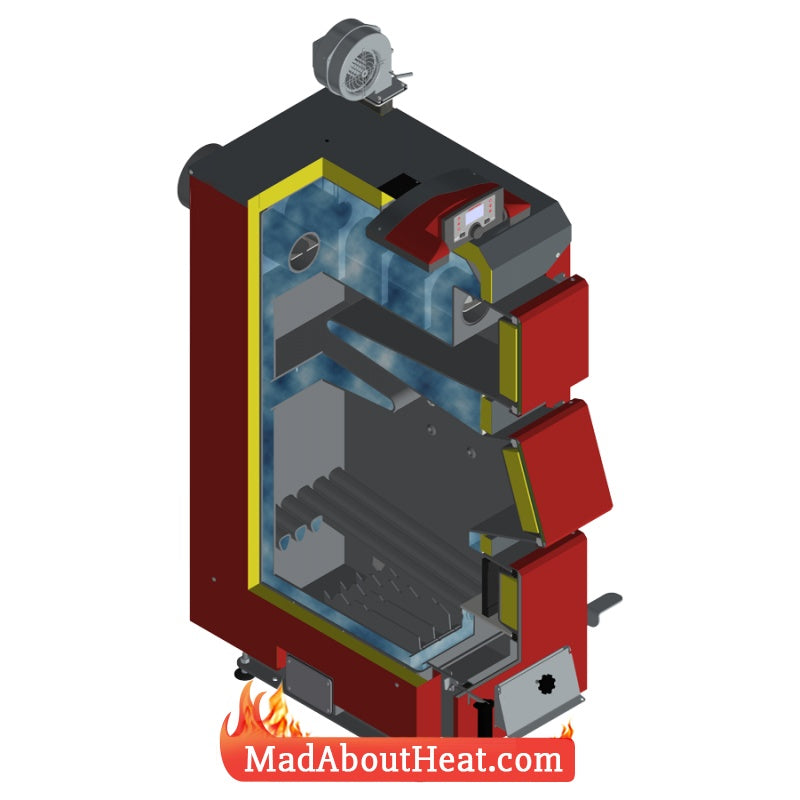

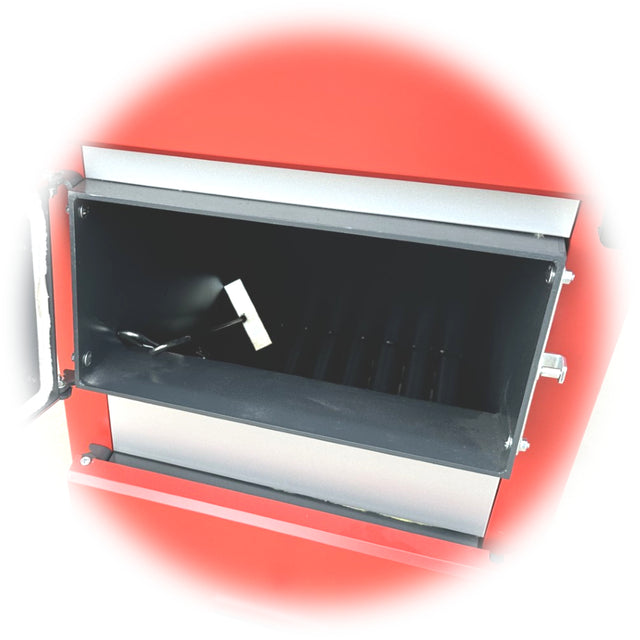

We would have to cut the boiler in half to fully appreciate the design and skilled work that goes in to our boilers. With the neck of the doors and exhaust, being only pieces of the boiler that are single skin, rest of the boiler, including bottom grate, firebox and upper tubes are all part of heat exchanger design giving 81-85% efficiency in transferring heat in to water.

5. Engineer free, own servicing.

Majority of our customers are focused on saving money on heating, so a boiler that burns cheap fuel but costs £1000's to service annually doesn't make sense. DWB and DWBi boilers are very simple to maintain and service. Main maintenance functions to be carried out are ash emptying every 1-2 weeks and heat exchanger cleaning every 4-12 weeks. The major cleaning procedure takes no longer than 10 minutes. Scraper and shovel are provided.

6. Large fire box.

All of our manually loaded boilers come with extremely large fire boxes, looking at the 30kW unit it has a 130 litre chamber and 40kW is 180 litres in volume. 50cm logs fit straight in.

7. Long refill times.

Large fire box design gives large fuel holding capacity, this gives long refill periods, 12hrs burn times are achievable and in conjunction with correctly sized buffer tank, a 1 fill in 24hr period is achievable.

8. Temperature control.

On DWB model, temperature control is done by a screw type thermostatic lever valve. It is a very simple and reliable system proven to work over the last 30+ years .

The DWBi however comes equipped with electronic controller system. It does not require encyclopedia size book as a manual, the controls are intuitive and easy to operate. (Support in operation available over the phone). The controller uses temperature sensors mounted on the boiler to control speed of fan thus amount of oxygen fire gets and operation of circulating pump. All controllers are programmed for optimum performance.

With the revisions carried out on regular basis, the DWB / DWBi multi fuel boilers are well finished with good solid feel and are able to burn wood, coal and variety of other solid fuels.

The DWB / DWBi biomass boilers are available in power outputs ranging from 12 – 50kW.

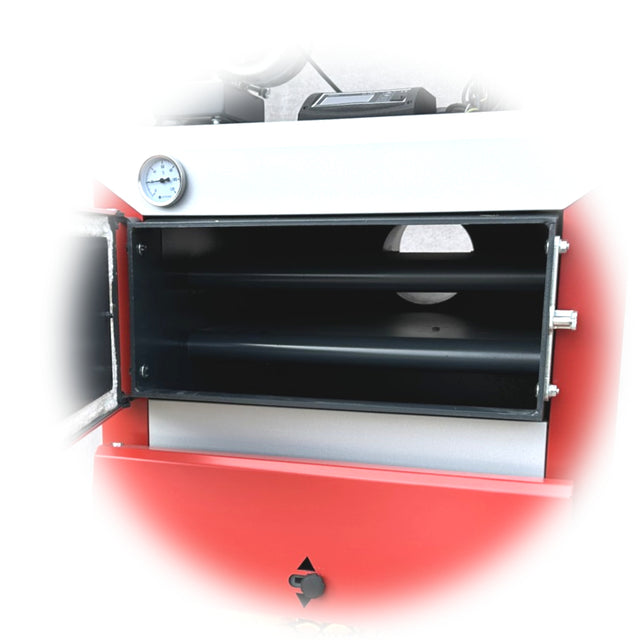

Taking a look around the boiler, the front has 3 openings, top, middle and bottom.

Top is a door for cleaning heat exchangers and access to flue.

Fuel loading is through large middle door.

Middle door also houses a secondary air supply flap, this allows unburnt gases to mix with fresh oxygen and reignite, giving a very clean gasification type burn.

Bottom door is for ash pan access.

To the side is a grate shaker lever, spent gases exit through baffled exhaust located at the rear controlled by lever located on the front top left part of the boiler.

Manufactured out of EN specification 5-6 mm steel plates, laser cut and welded internally.

A electrical supply is needed, very low consumption, DWB boilers can work with no electricity. Ideally suited for open / vented plumbing type system but can work happily with pressurized systems.

Fill up light and forget system thanks to electronic controller.

Refills vary with boiler output as does fire box size, but expected burn time, using coal or wood, to be 3-4 hours for smaller units and up to 8-12 hours on bigger machines.

As with the rest of our items this wood boiler is a 100 % European product.

Please Note

Shape or size may vary slightly as products evolve and are constantly updated.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Product features

Hover over + to see inside.