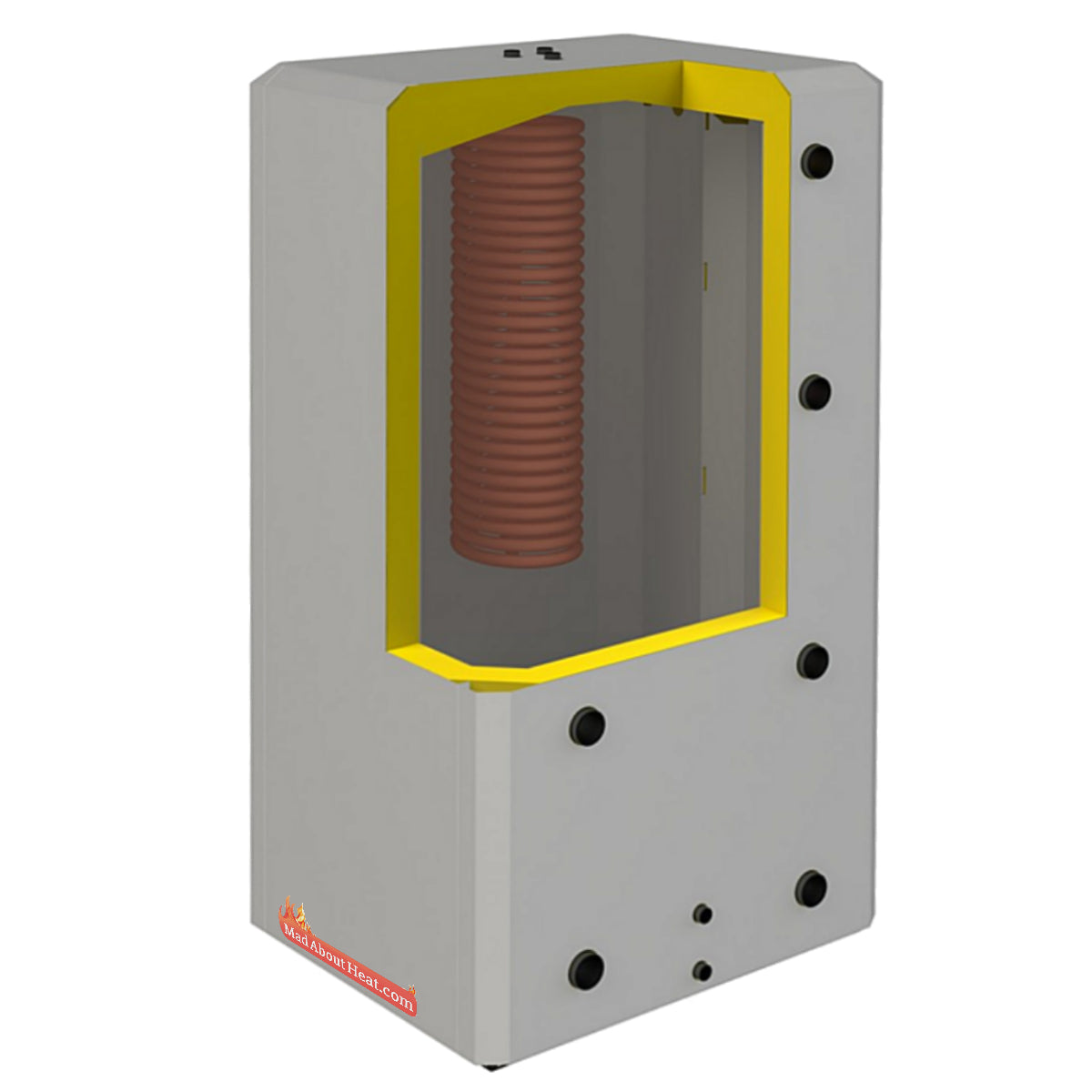

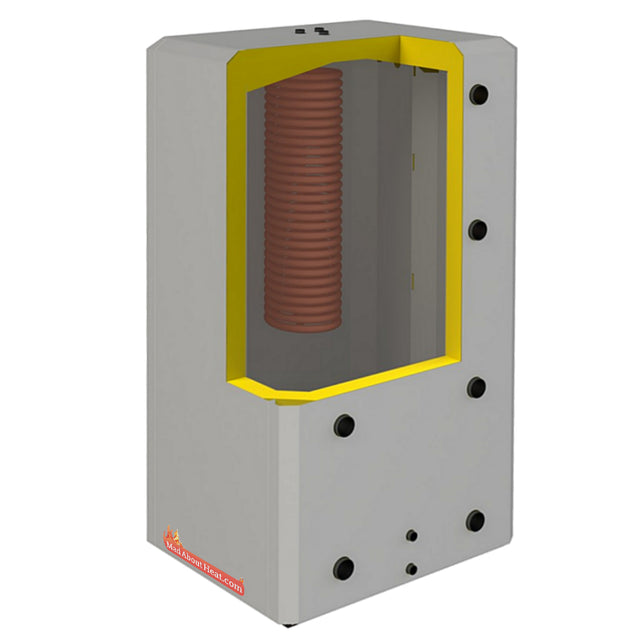

Buffer tank with internal coil, thermal store with coil.

Buffer tank with internal coil, thermal store with coil. - 500 Litres with coil is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

These items are bulky and require delivery on a pallet, please contact us to arrange.

Solid well made design.

Description

Description

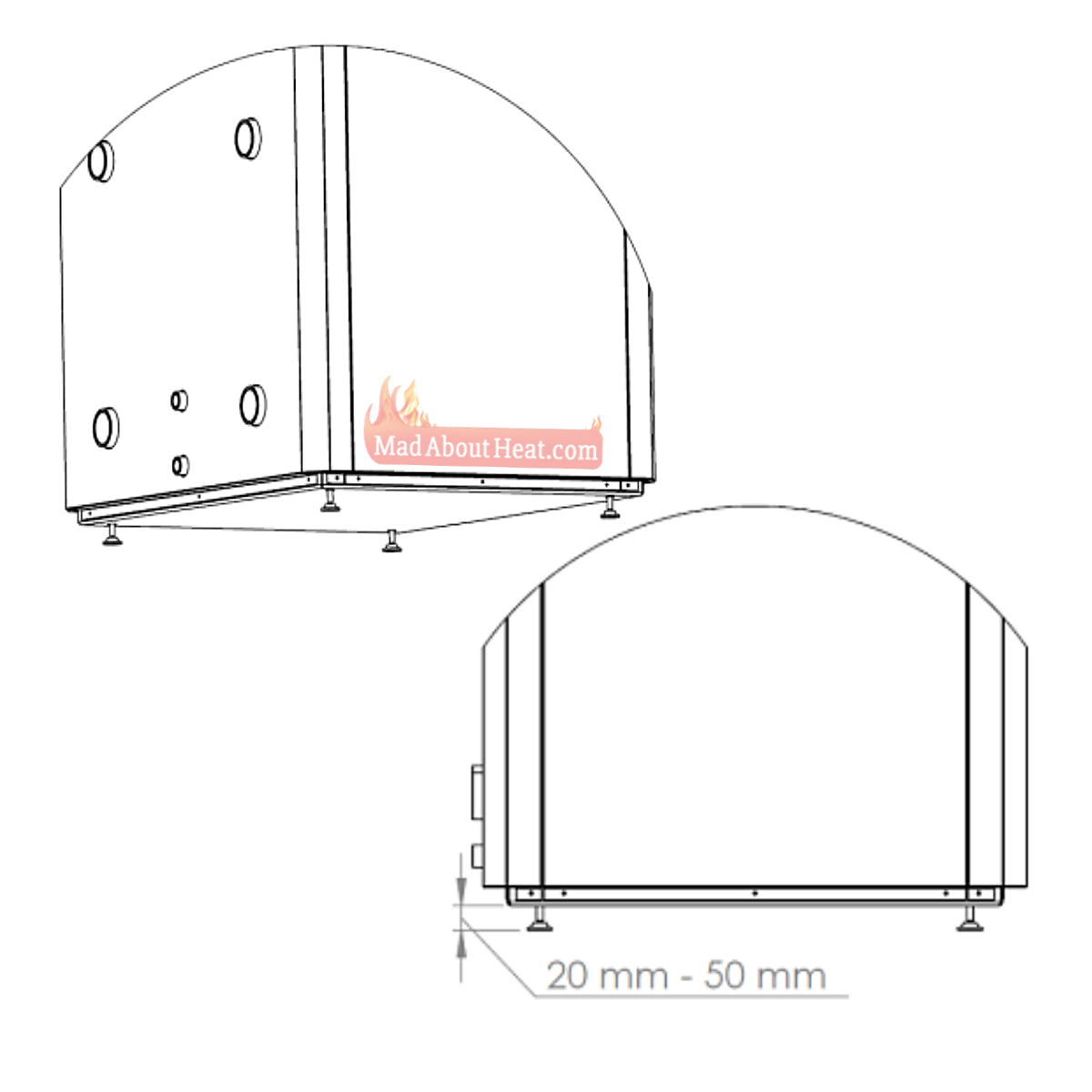

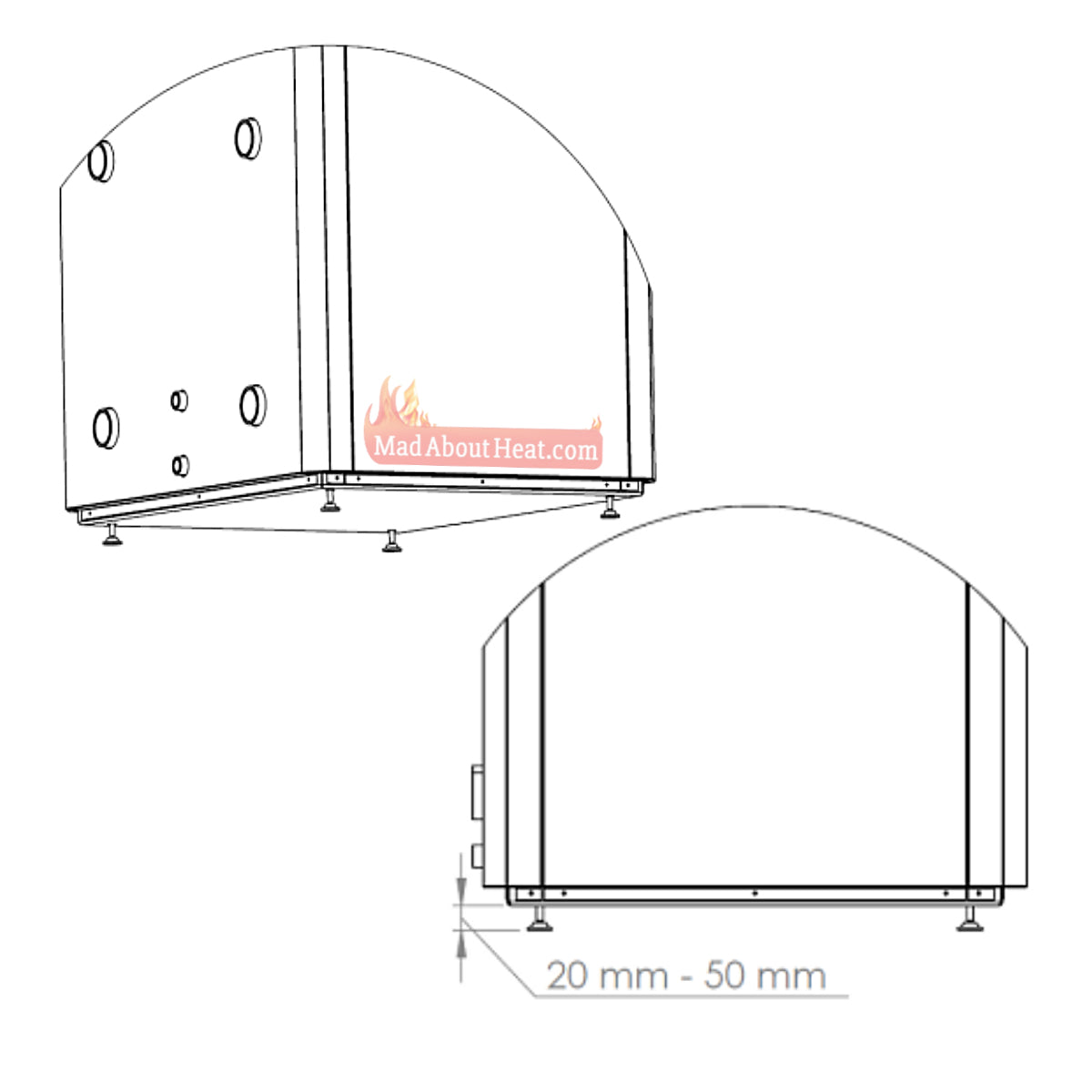

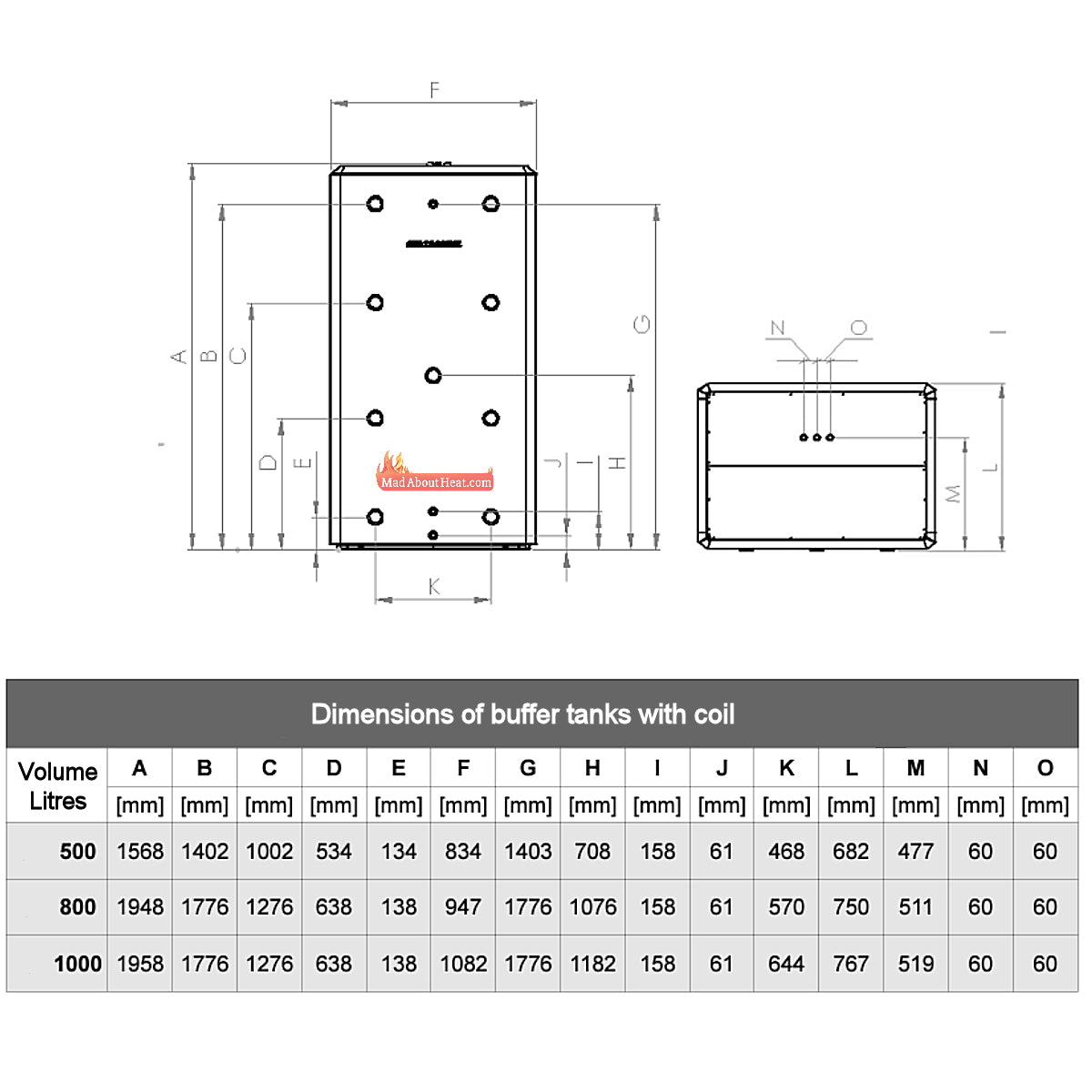

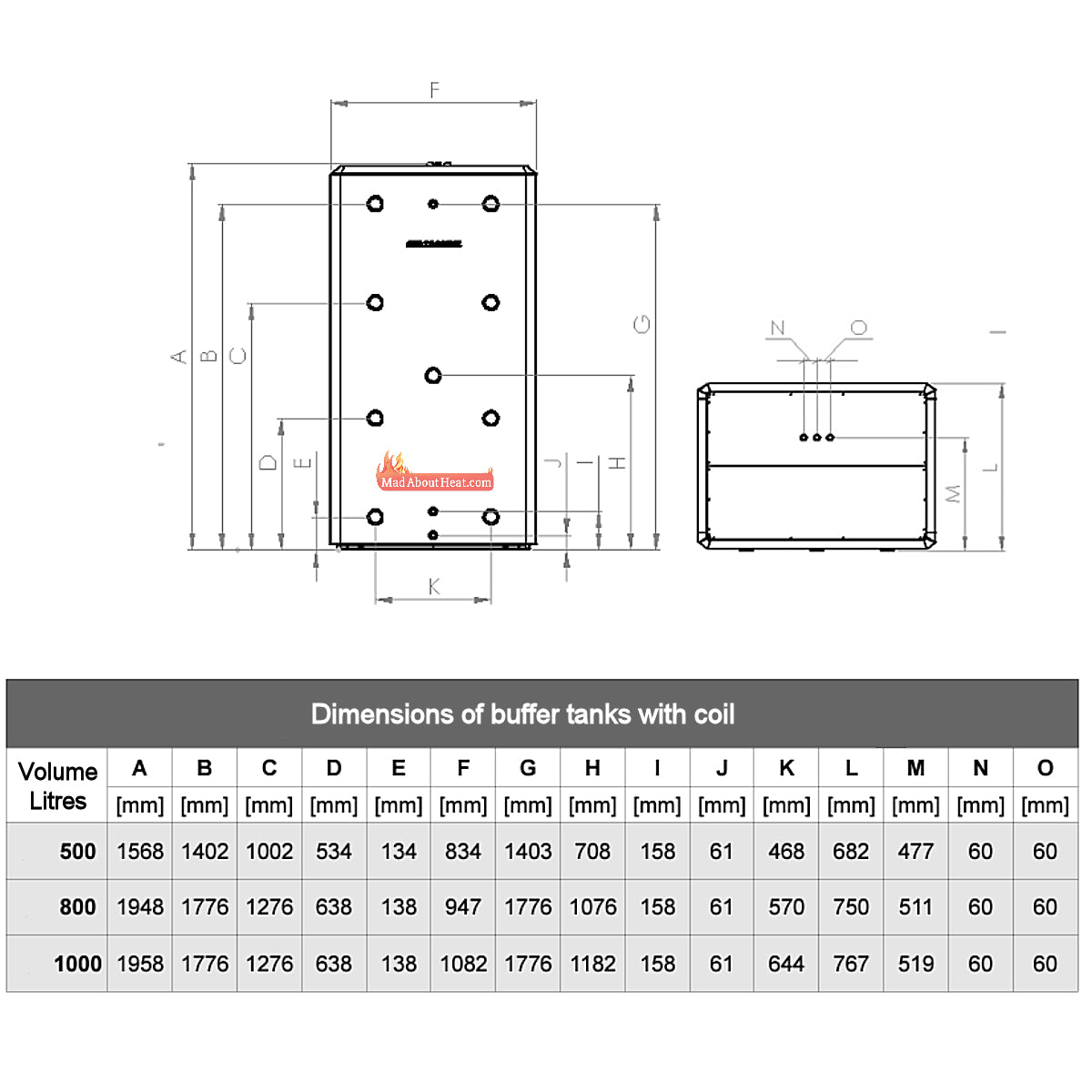

Buffer tank with internal coil, thermal store with coil.

A buffer tank is a hot water storage tank also called an accumulator tank or a thermal storage tank, in a nut shell it is a large, well insulated water cylinder having minimal thermal loss and is designed to smooth out any great temperature oscillations as well as storing heat for long after the boiler runs out of fuel.

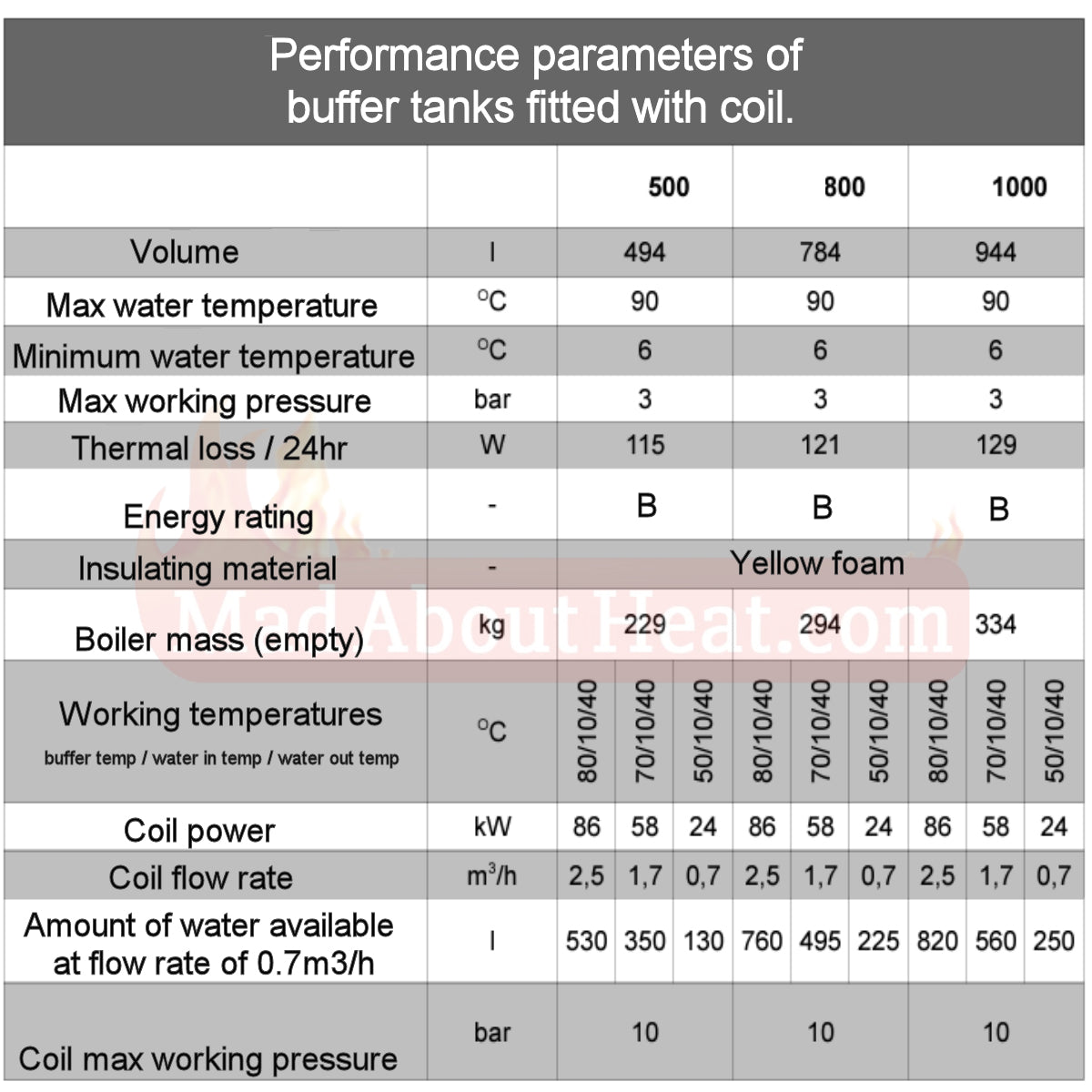

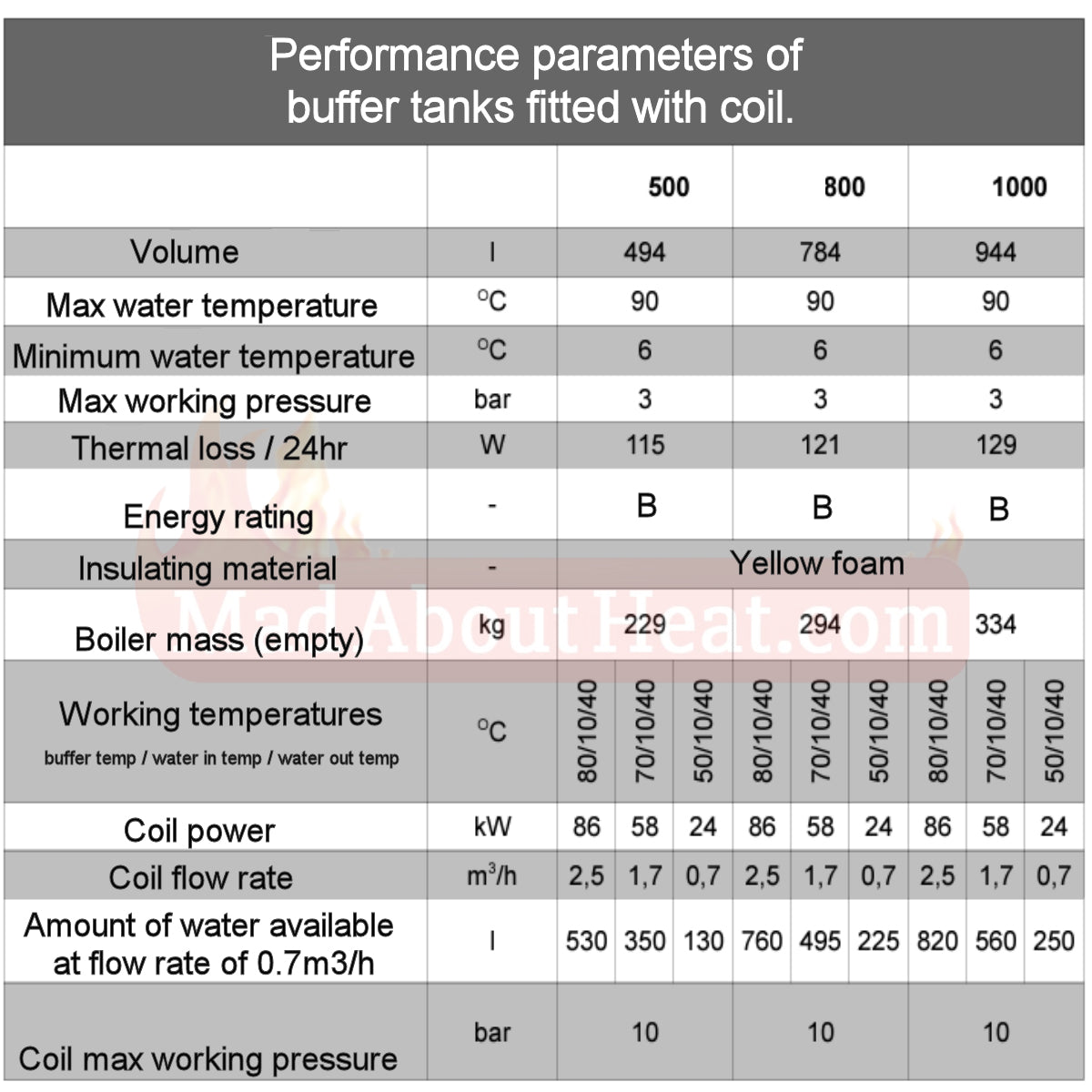

With the addition of a copper coil with fins, the buffer tank can be used to provide hot water on demand without the need for hot water cylinder. See tables for flow rates and performance.

Looking at a scenario where user using DWBi boiler, user has filled the boiler with fuel and allowed the temperature to build up. Assuming the first load of fuel was not quite enough for the property to reach the desired temperature, user then topped up the boiler with more fuel.

The solid fuel boiler was then left to run for approx. 20-30 minutes, long enough for a good size cherry to form inside the fire box. A desired house temperature was then achieved causing thermostats to shut off. This would cause the boiler to reach its set temperature and the controller will shut off oxygen supply to the fire in order to stop the cycle.

With the oxygen shut off, residual heat from the cherry still radiating is now causing temperature to build up inside of the boiler, how much by, would be directly related to the size of cherry v boilers size ratio or more down to how much extra fuel was added during last top up. This situation can cause temperature to increase by as much as 20 - 30 degrees C.

To harness this and to keep the temperature steady, a leak off radiator or a buffer tank is commonly used. The accumulator tank being more efficient solution of all systems as it will even out any temperature changes so that a steady flow is maintained and stores the extra heat for when it is needed. If the boiler and buffer are well matched to the property size, temperature change is rarely more than +/- 8 degrees C. whilst maintaining good heat delivery for as long as 18hr during winter months from one boiler fill.

It is also worth mentioning that the burn efficiency, lower emissions and longer life span of equipment can be observed with the use of buffer tanks in biomass central heating systems.

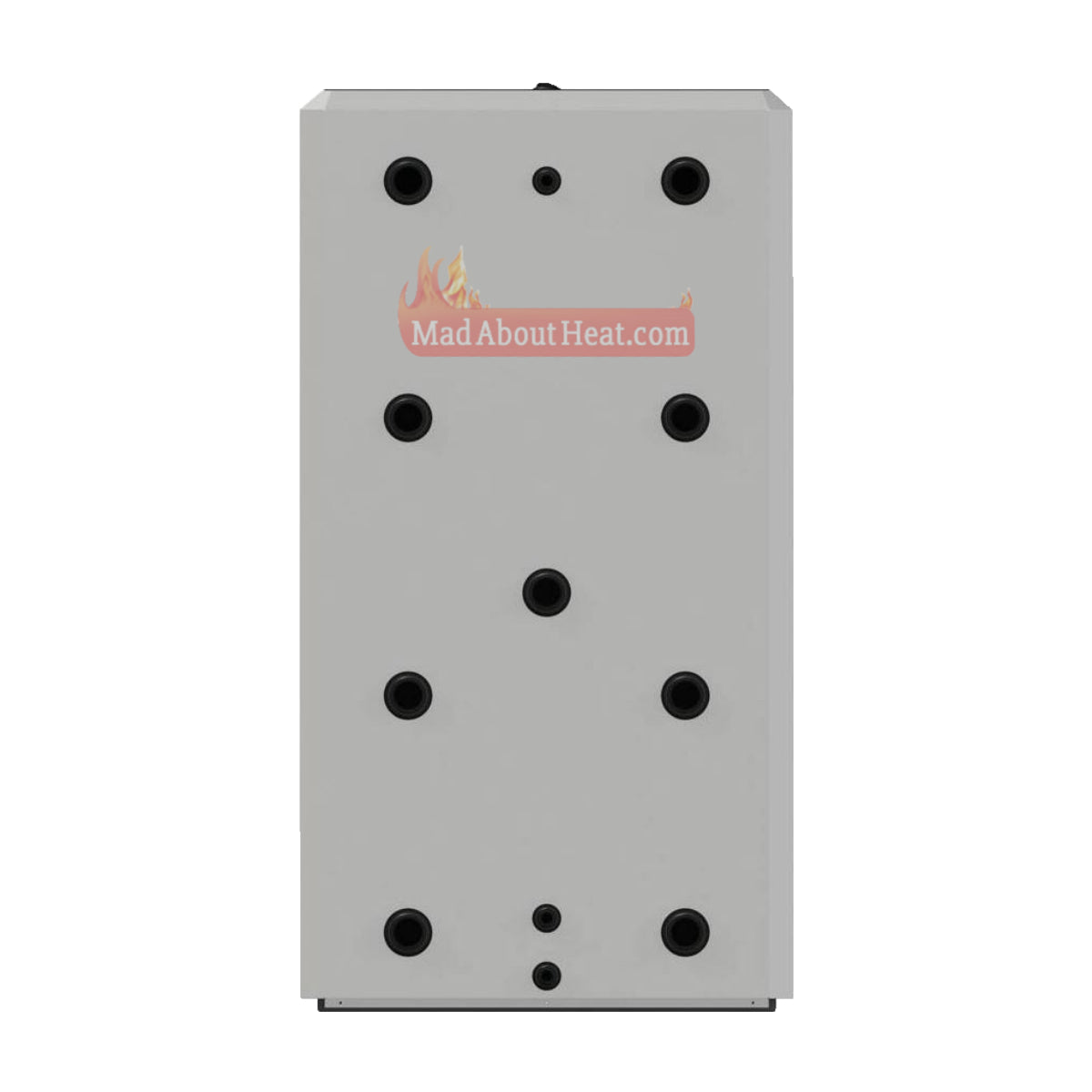

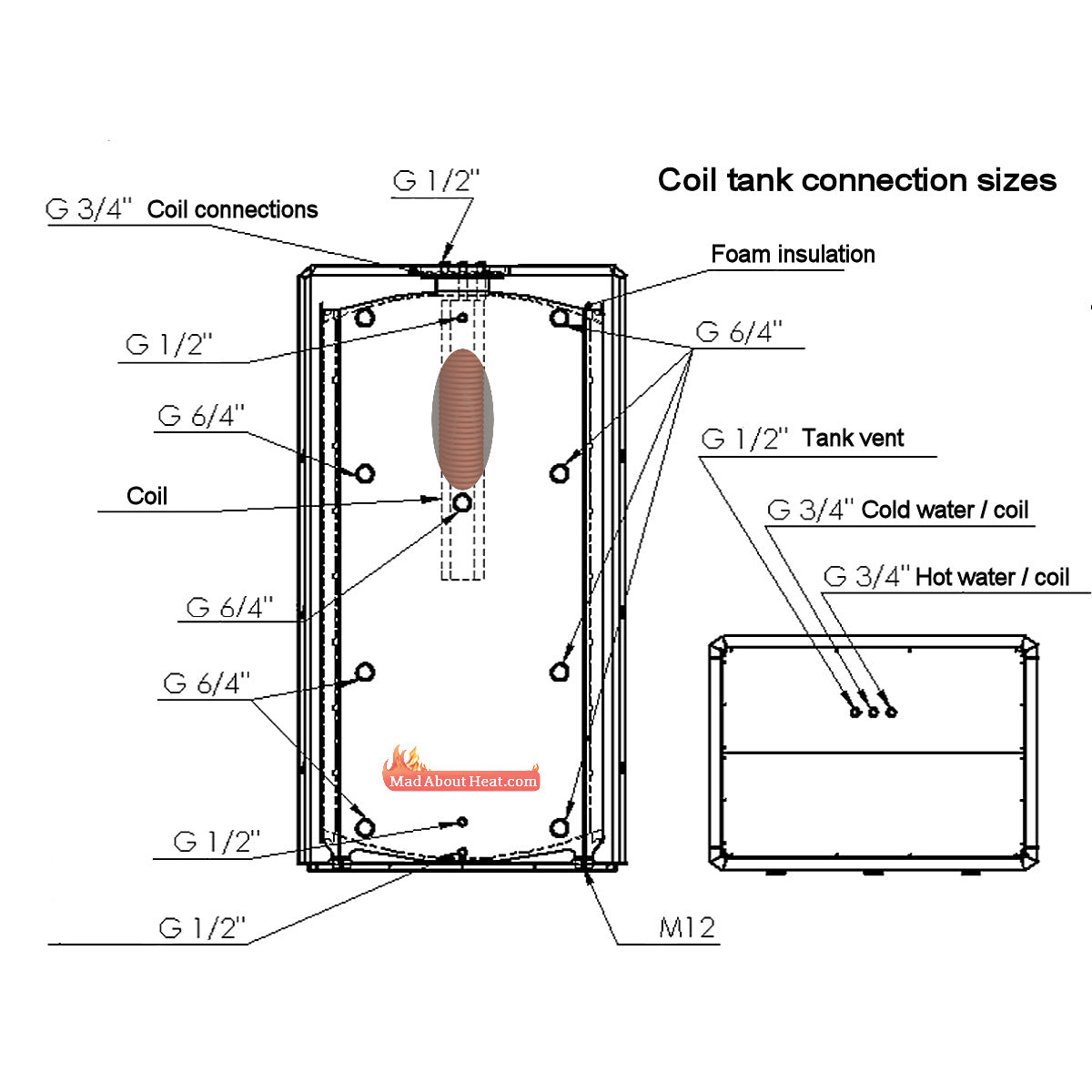

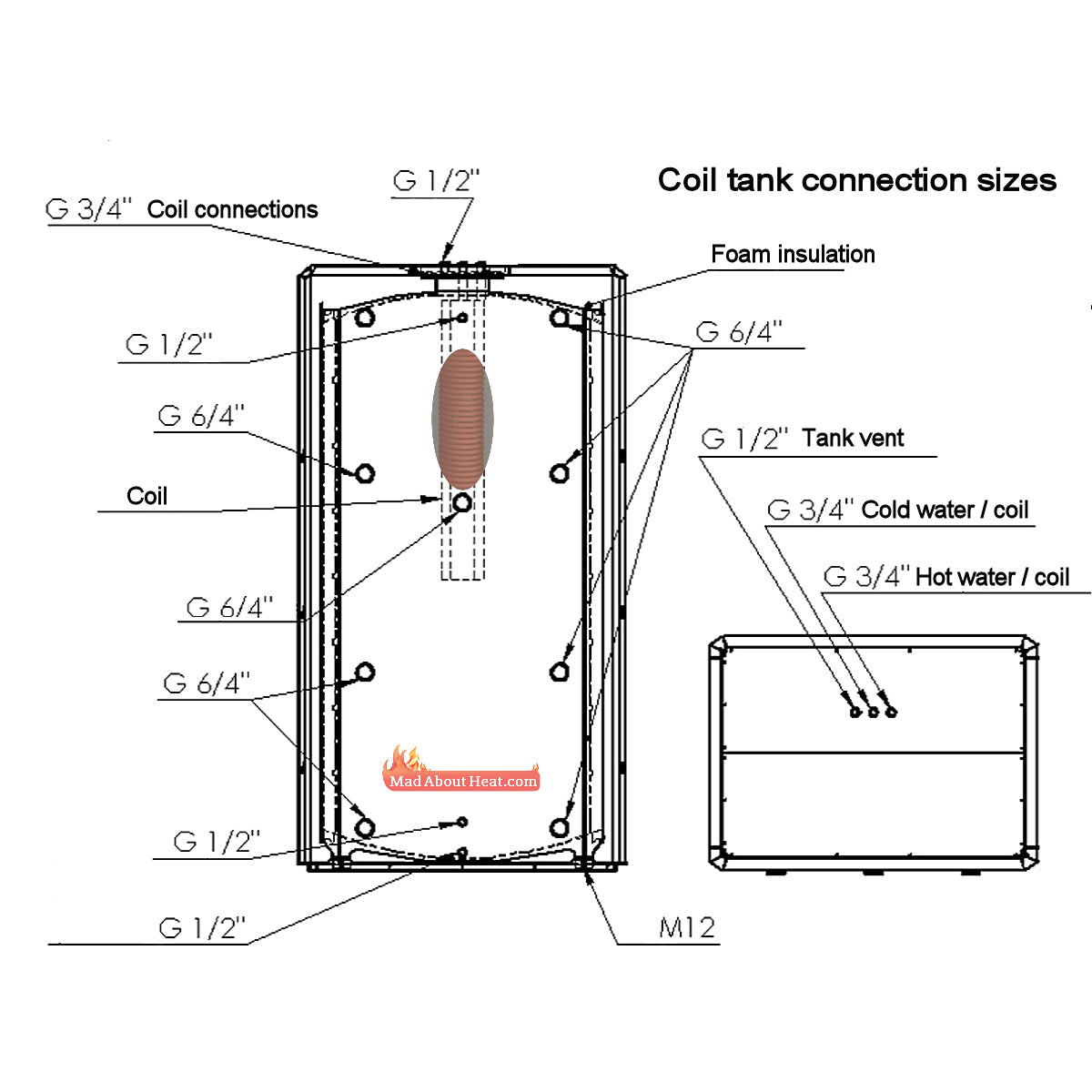

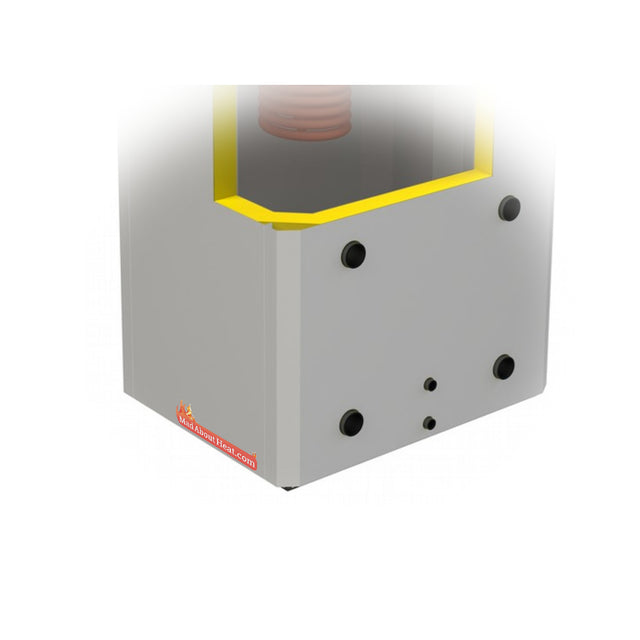

There are 9 large 1&3/4 inch connections on the buffer tank, this enables the unit to be connected to multiple heat sources or be used as a immersion tank. There are also number of smaller ones, which are used for draining of the system, bleeding, inserts for temperature gauges or a connection of pressure vessel.

When sizing a tank many different variables are taken in to consideration and its best to give us a call so that equipment chosen performs to users satisfaction.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Buffer tanks, thermal store.

Key points distinguishing our products from others.