GSi 21kW Biomass Gasification Wood and Logs Boiler Pyrolyzer

GSi 21kW Biomass Gasification Wood and Logs Boiler Pyrolyzer - GSi 21kW is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

These items are bulky and require delivery on a pallet, please contact us to arrange.

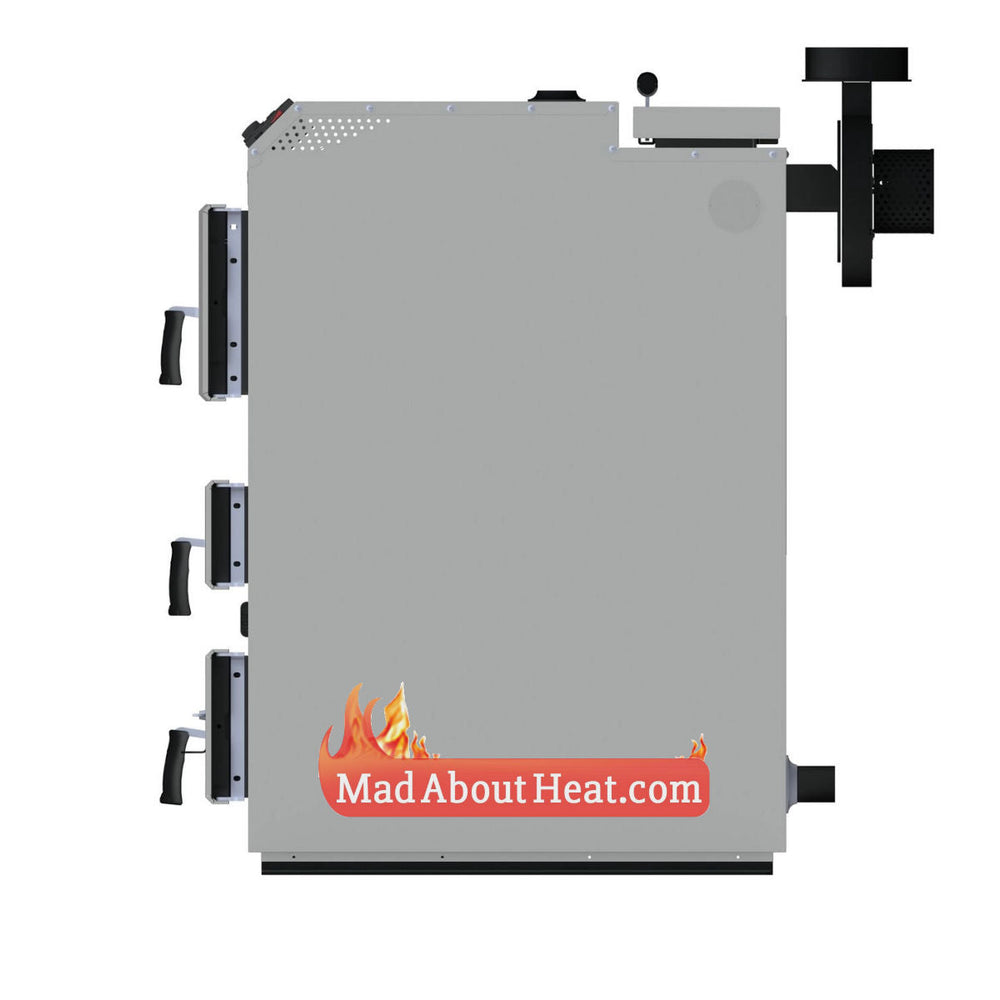

Solid well made design.

GSi 21kW Biomass Gasification Wood and Logs Boiler Pyrolyzer

Central Heating & Hot Water Solid Fuel Boiler.

The GSi range of boiler are the latest in technology of extracting heat from renewable sources of energy such as biomass.

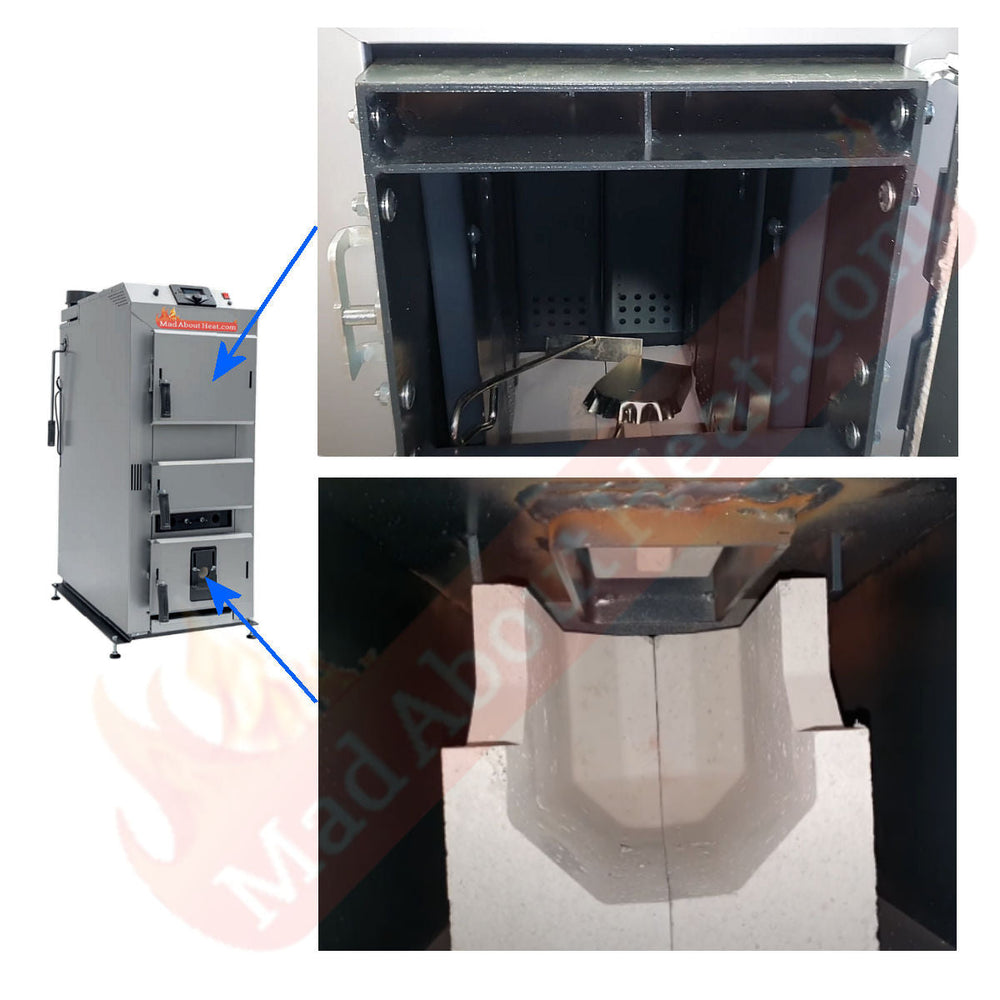

The process of gasification or pyrolysis involves burning of a combustible matter, carbonizing, without oxygen, this occurs at high temperatures of 500C and above.

The produced gases are then ignited in a separate chamber in the lower part of the boiler and then flames are fed through rear heat exchangers to heat water.

These boilers are designed to work with buffer tanks as they need constant cooling.

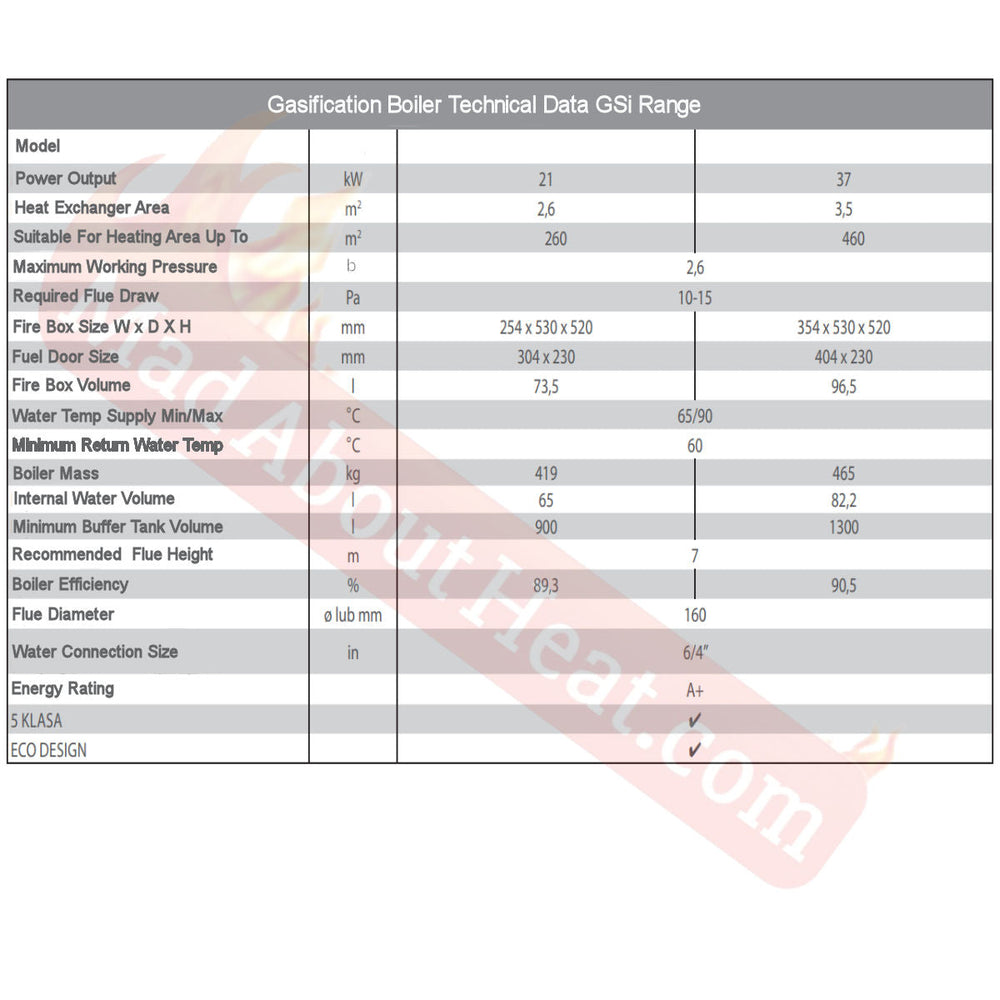

Our GSi gasification boilers produce less pollution, they are also 5th Gen and Eco Design compliant.

Key points about the GSi boilers.

1. Ability to burn wide variety of fuels.

When designing the GSi range of boiler the key factor was the ability to burn a wider range of biomass fuel. These boiler are designed to burn logs and wood as a primary fuel, but are also able to combust peat, turf and man made wood based products providing key parameter is observed, the moisture content must be within 10 and 20%.

2. Simple in design and operation.

Many of us used or still use an open fire or a stove and have experienced of what is involved performing this task however key difference between a boiler and stove being that GSi boiler are less labour intensive in exploitation.

Due to higher burn temperature and increased efficiency GSi boilers are designed to heat vast masses of water, with 1 load per day being easily achievable.

3. Solid build and made to last.

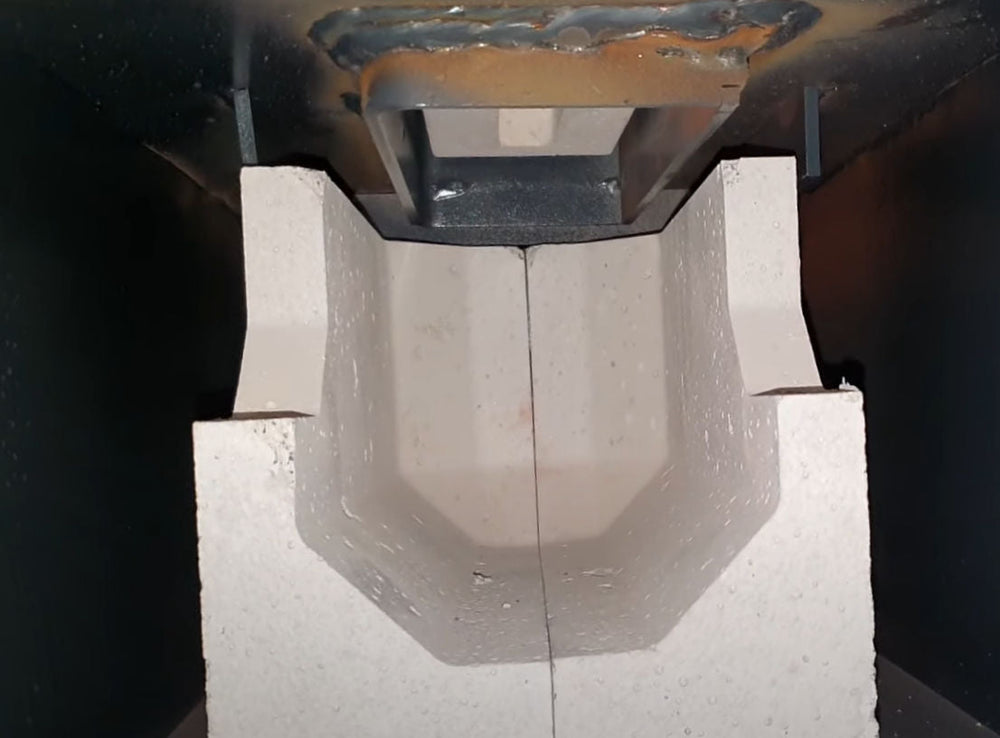

As with all of our products, the GSi boilers are engineered to last and are made from 5-6mm purpose made steel, made to resist heat stretch cracks and corrosion from acidic fuels. The high temperature places are lined with ceramic sinks and deflecting curtains.

From the moment we hold the handle and open the door, the solid well made design is instantly felt. Weld joints are on the water jacket side and kept to minimum with folding carried out through majority of the boiler. Realistic life expectancy is 20+ years.

4. High efficiency.

We would have to cut the boiler in half to fully appreciate the design and skilled work that goes in to our boilers. The GSi gasification boilers have a very high efficiency, 89.3 and 90.5% for 21kW and 37kW respectively.

5. Engineer free, own servicing.

Majority of our customers are focused on saving money on heating, so a boiler that burns cheap fuel but costs £1000's to service annually doesn't make sense. DWB and DWBi boilers are very simple to maintain and service. Main maintenance functions to carried out are ash emptying every 1-2 weeks and heat exchanger cleaning every 4-12 weeks. The major cleaning takes no longer than 10 minutes. Scraper and shovel are provided.

6. Large fire box.

All of our manually loaded boilers come with extremely large fire boxes, looking at the 30kW unit it has a 80 litre chamber and 40kW is 150 litres. 50cm logs fit straight in.

7. Long refill times.

Large fire box design gives large fuel holding capacity, this gives long refill periods, 12hrs burn times are achievable.

8. Temperature control.

The GSi boiler temperature control is done by adjust exhaust fan speed thus draw through the combustion chamber in the boiler.

The fan speed is calculate by the intelligent computer which looks up data from water temperature sensor, exhaust gas temperature sensor, surrounding environment temperature sensor and feed back from fan speed.

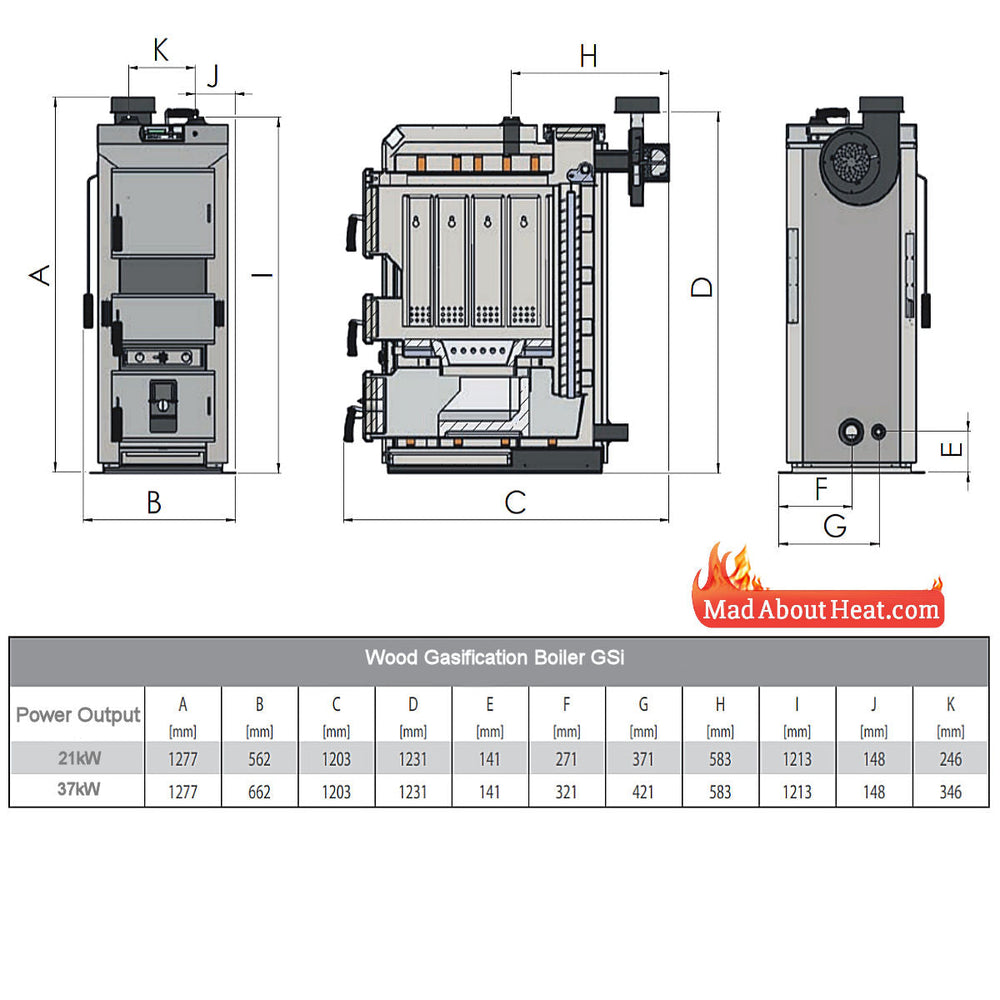

GSi boilers are available in variable power outputs of 21 & 37kW.

Taking a look around the boiler, the front has 3 openings, top, middle and bottom.

Top large door is used for loading fuel.

Lighting of the boiler and starting the gasification process is done through middle door.

Bottom door is for ash pan access and houses flame look up glass, this is used to adjust mixture.

To the side is a shaker lever which moves internal cleaning elements up and down thus increasing heat exchange process and eventually allowing spent gases to exit through baffled exhausts located at the rear.

Manufactured out of EN specification 5-6 mm steel plates, laser cut and welded internally.

A electrical supply is needed, very low consumption. Ideally suited for open / vented plumbing type system but can work happily with pressurised system.

Fill up light and forget system thanks to electronic temperature controller.

Refills vary with boiler output as does fire box size, but expected burn time, using coal or wood, to be 6-7 hours for smaller units and up to 8-12 hours on bigger machines.

The GSi boilers require buffer / accumulator tank in order to operate safely and efficiently.

As with the rest of our items this wood boiler is a 100 % European product.

Please Note

Shape or size may vary slightly as products evolve and are constantly updated.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.