madaboutheat.com | SKU:

CTBi 200kW

CTBi 200kW Commercial Automated Wood Pellet Biomass Coal Central Heating Boiler

Regular price

£24,100.00 GBP

Unit price

/

Unavailable

Tax included

CTBi 200kW Commercial Automated Wood Pellet Biomass Coal Central Heating Boiler - CTBi 200kW is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Some of our items are bulky and require delivery on a pallet, please contact us to arrange.

Solid well made design.

CTBi 200kW Commercial Automated Wood Pellet Biomass Coal Central Heating Boiler.

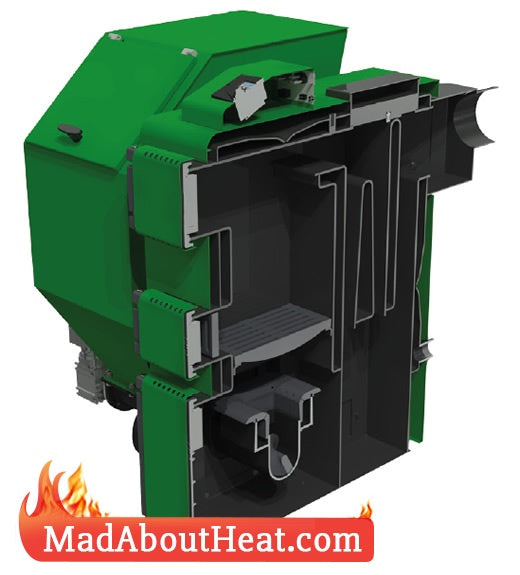

CTBi Wood pellet boilers with multi fuel capability, rear heat exchanger system allowing for increased size of firebox. Suitable for 50/50 automatic and manual solid fuel burning.

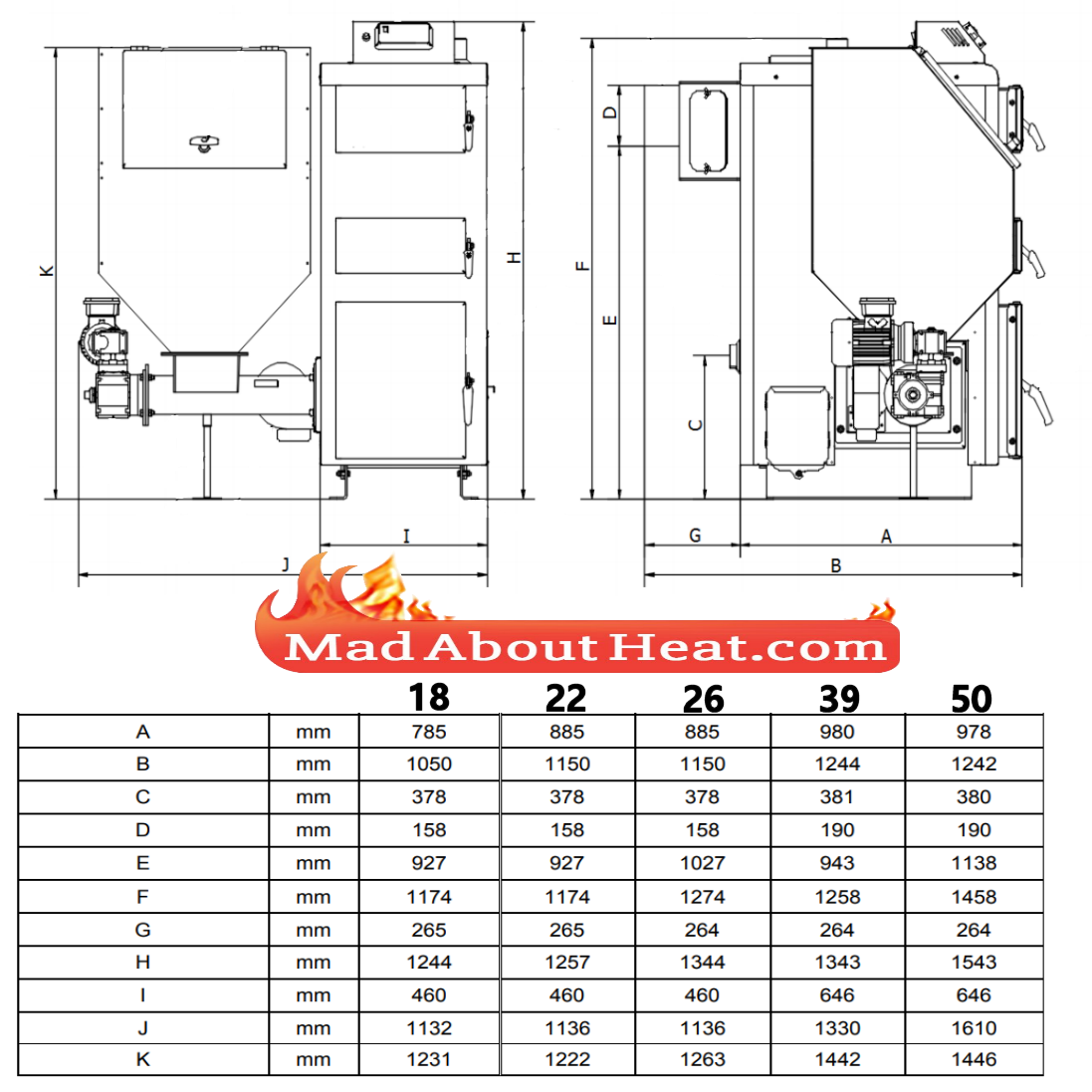

Power range is 18-200kW.

The green pellet burners in our shop are the CTBi range, well known for their simplicity in design and operation whilst providing reliable and efficient performance at affordable costs.

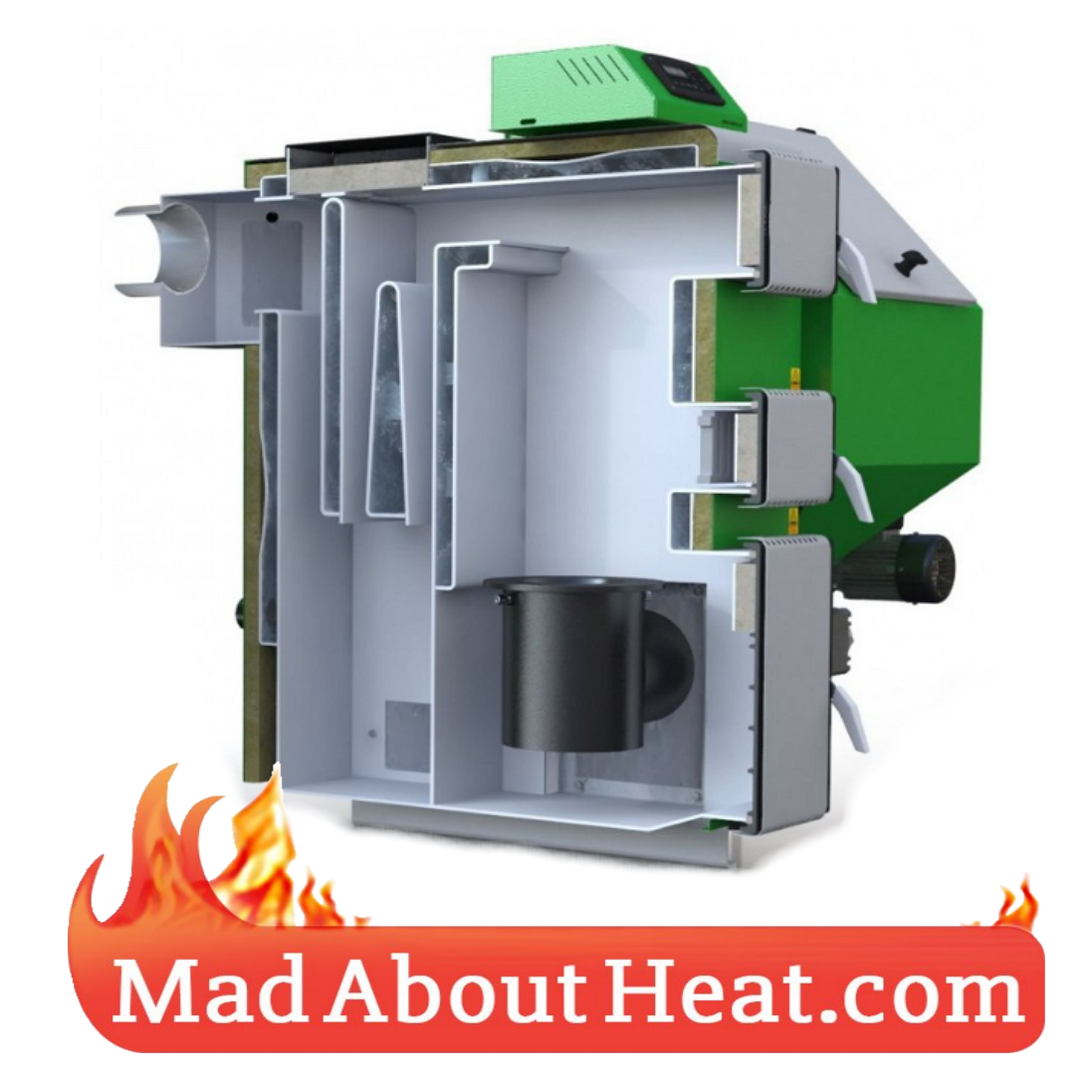

The no nonsense approach to automatic multifuel boiler design, utilities on increased length of flame and hot fumes gases exposure to heat exchanging elements. TPBI model unlike other boilers we sell, are achieving higher efficiency values because of location of the heat exchanger. Whereas the PBI or DPBI units have heat exchanger located in the upper part, CTBi burners try to centralise the heat by locating most of the channels towards the back. Although the grate is removable the multi fuel capability is already on par with smaller manual and semi manual boilers, this being due to the heat exchanger plates being located at the rear. The overall boiler height is reduced and is more user friendly for most, please see the diagram picture. Although the self ignition module is available as an option on this model of the multi fuel boilers, the solid design working in conjunction with top of the range controller makes most of fuel to increase overall efficiency and making do without the module.

In the automatic mode the pelletised fuel is stored in a hopper, pellets should be no bigger than 20mm cube and can be wood, pea coal, slack or other fuel in that form. Inside the hopper which is attached to one side, is fuel which is delivered by auger system to the centre of firebox where air is injected around the burn zone to excite the flame. This process is a standard system across most of boilers that are currently in production.

When loading the boiler manually with the likes of wood, coal or other solid fuel, the middle and top door is used allowing to take full advantage of the located at the rear, heat exchanger plates giving almost like semi automatic boiler, size of the firebox.

The computer located on top, is in control of air quantity, fuel supply rate and 2 water pumps.

A build in boiler flame protection system safeguards fuel store making the burner exploitation a safe and reliable operation.

In Parameters table below, shown are individual unit dimensions and available power outputs.

High efficiency

Long rear re-circulation

Hopper refills 3-21 days (depending on temp)

Solid finish

Modern controller

Cleaning periods 2-3 months

Ash emptying 1-2 months

Multi fuel capability

Automatic fuel feeding

Ideal for all central heating applications vented or pressurised / sealed systems and we suited for burning most of solid fuels. The CTBi range of multifuel wood pellet boilers can also be used for working in conjunction with other boilers of different fuel and to provide hot water for under floor heating and swimming pools.

Relevant European approval.

As with the rest of our items this wood boiler is a 100 % European product.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.