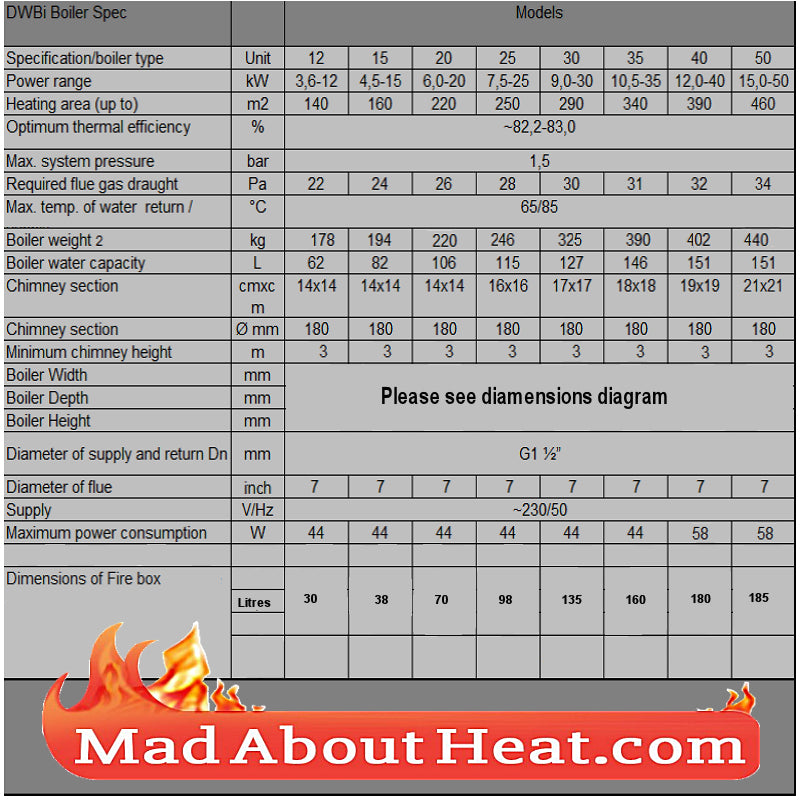

DWBi 15kW, multi fuel boilers, burn wood, logs, shrubs, peat, coal.

DWBi 15kW, multi fuel boilers, burn wood, logs, shrubs, peat, coal. - DWBi 15kW is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

These items are bulky and require delivery on a pallet, please contact us to arrange.

Solid well made design.

Description

Description

DWBi 15kW, multi fuel boilers, burn wood, logs, shrubs, peat, coal.

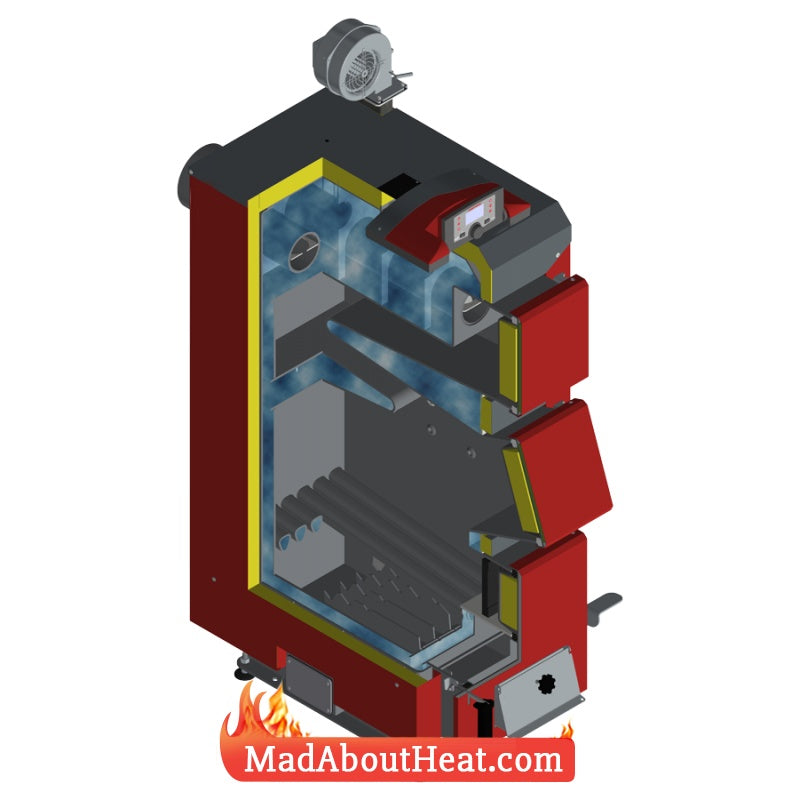

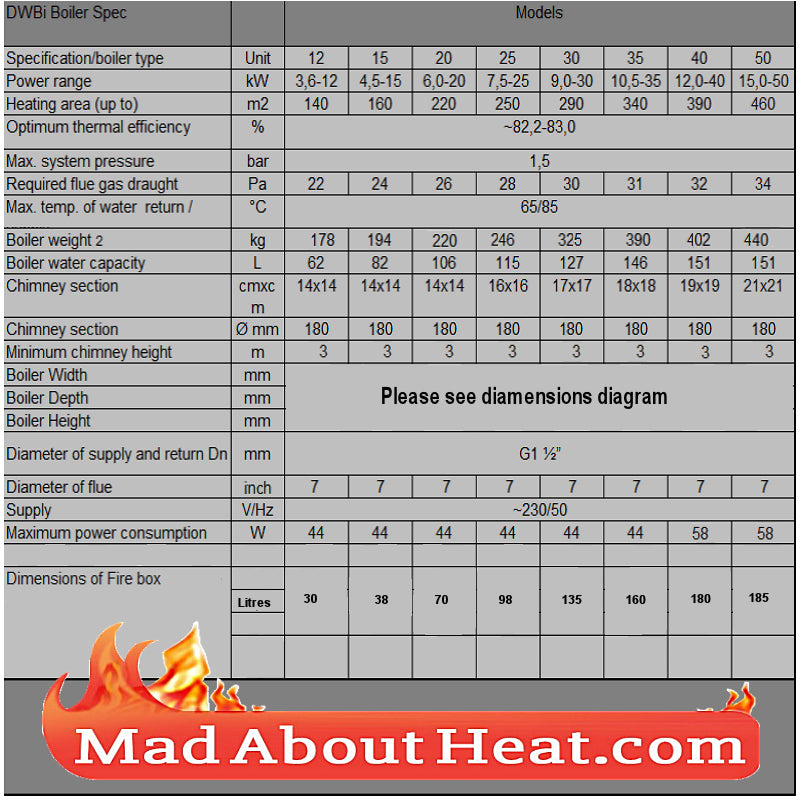

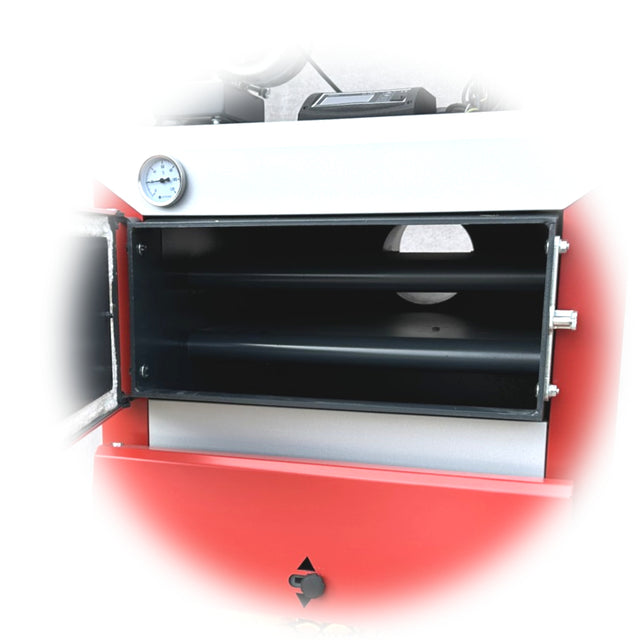

The DWBi 15kW wood burning boiler is fan assisted to give better control over fire efficiency, faster temperature build up and a more complete longer burn times.

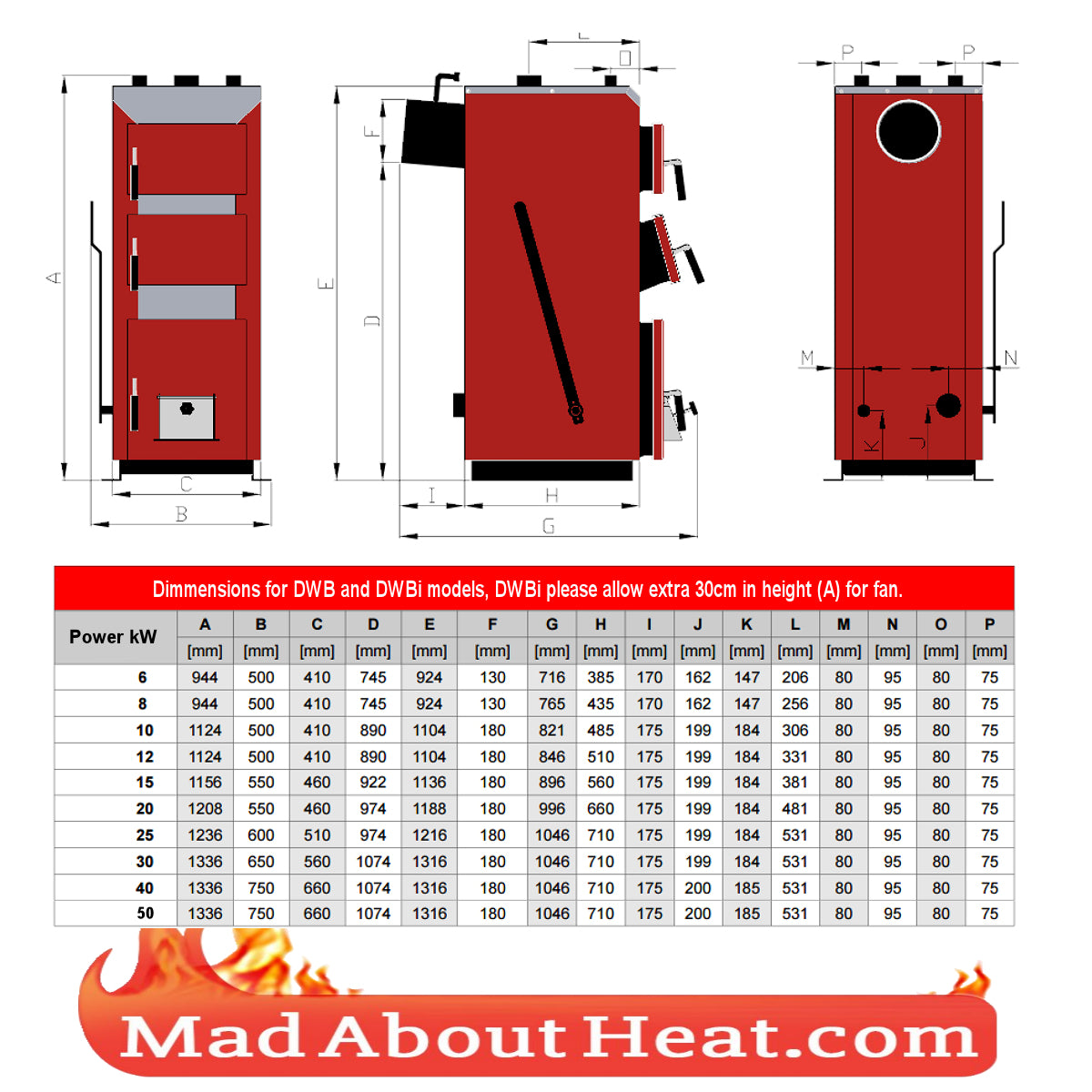

Small on size but big on power, this solid fuel boiler can be installed in an average size home with a total square area of around 130m2.

This log boiler will heat your home and provide consumable hot water, can be plumbed in open vented or closed central heating system.

The DWBi range can also be used with our buffer tanks and our hot air blowing fan radiators.

please also consider our thermal relief valve, designed to release hot water and refill the boiler with cold water shall an emergency situation arise.

For full product video please click HERE.

For DWBi full product page please click HERE.

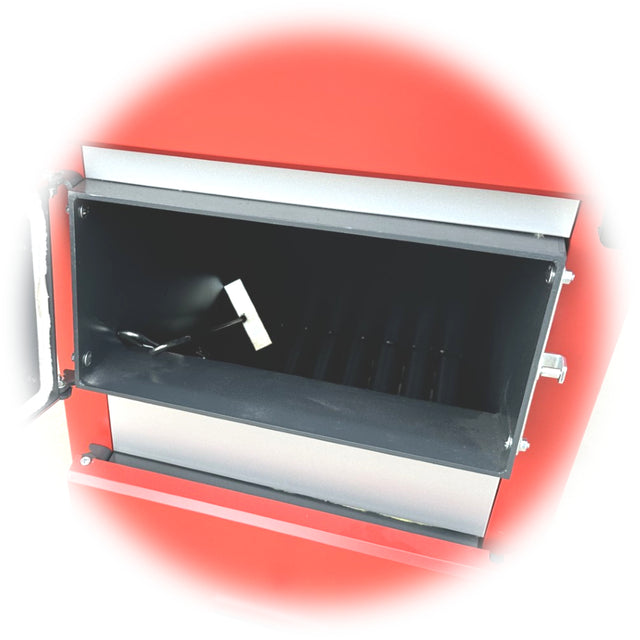

Manufactured out of EN specification 6-7 mm steel plates, laser cut and welded internally.

An electrical supply is needed, albeit very low consumption, DWBi boilers can also work with no electricity.

Fill up, light it and walk away system thanks to electronic controller keeping a watch full eye over combustion parameters and temperature control.

Refills vary with boiler output as does fire box size, but expected burn time, using coal or wood, to be 3-4 hours for smaller units and up to 8-12 hours on bigger machines.

As with the rest of our items this wood boiler is a 100 % European product.

Please Note

Shape or size may vary slightly as products evolve and are constantly updated.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Product features

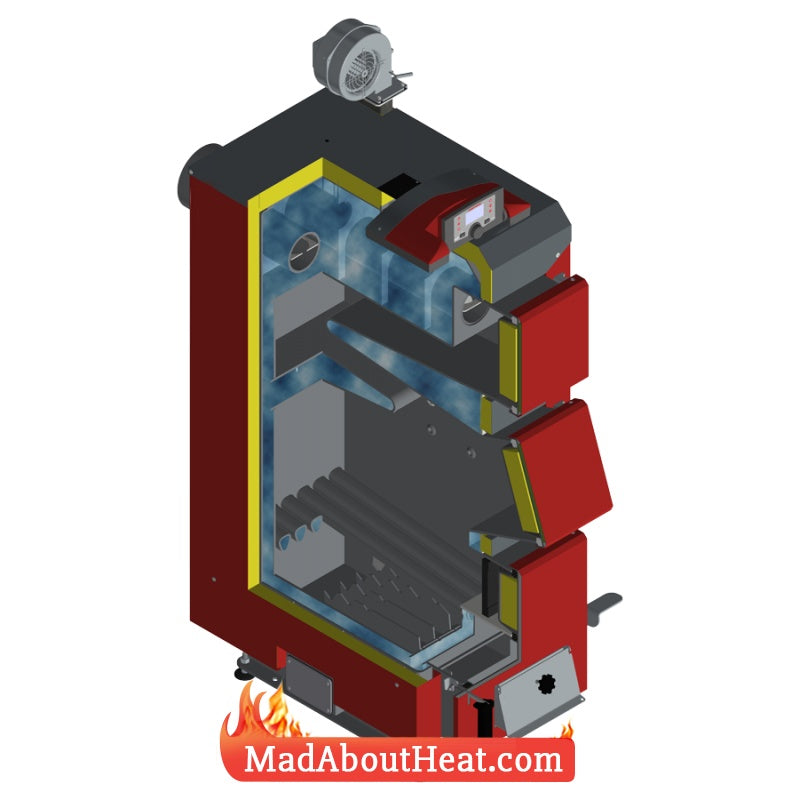

Hover over + to see inside.