madaboutheat.com | SKU:

WBi 40kW

WBi 40 kW Solid Fuel Biomass Central Heating Boiler

Regular price

£3,650.00 GBP

Unit price

/

Unavailable

Tax included

WBi 40 kW Solid Fuel Biomass Central Heating Boiler - WBi 40kW is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

These items are bulky and require delivery on a pallet, please contact us to arrange.

Solid well made design.

Description

Description

WBi 40 kW Solid Fuel Biomass Central Heating Boiler

WBI boilers bridge gap between multi fuel burning capability of solid fuel burners and an automatic technology of wood pellet type machines.

Fan assisted air injected multi fuel wood, coal and light waste boiler.

These boilers range with output from 9kW to 50kW

Based loosely on the well established and proven WB boiler chassis, the WBI range of multi fuel boilers makes most of multi fuel capability by introducing computer controlled fan assistance to aid burn process.

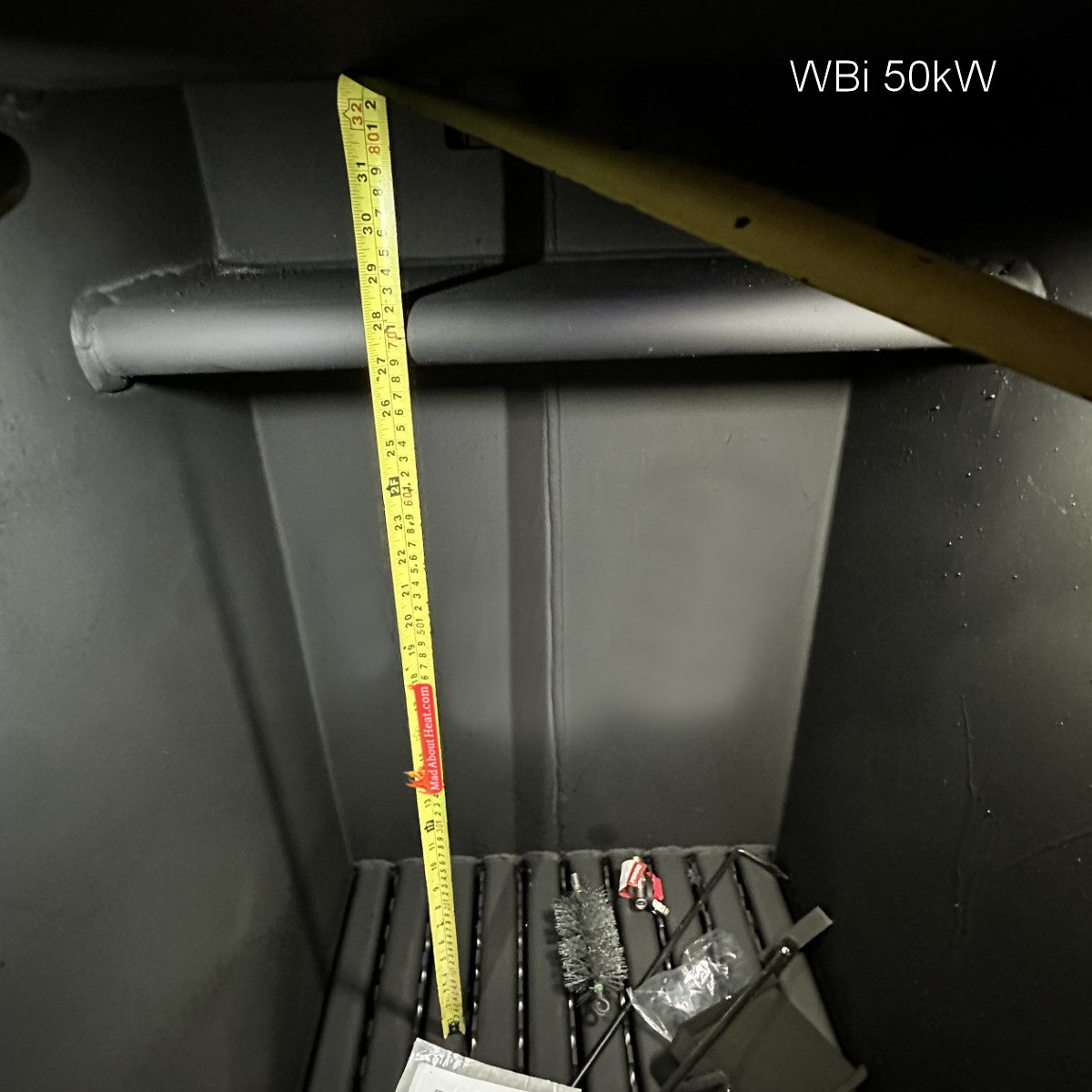

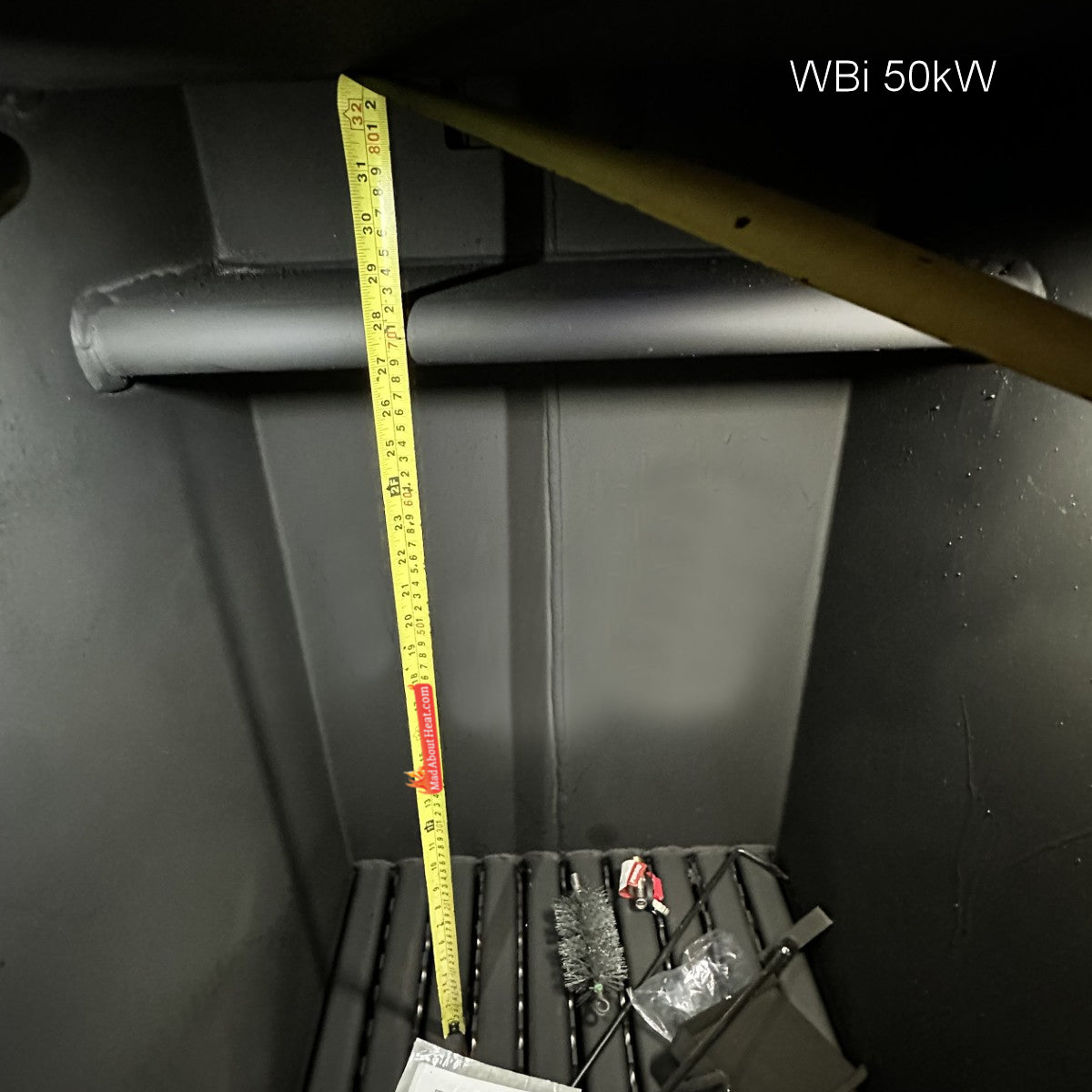

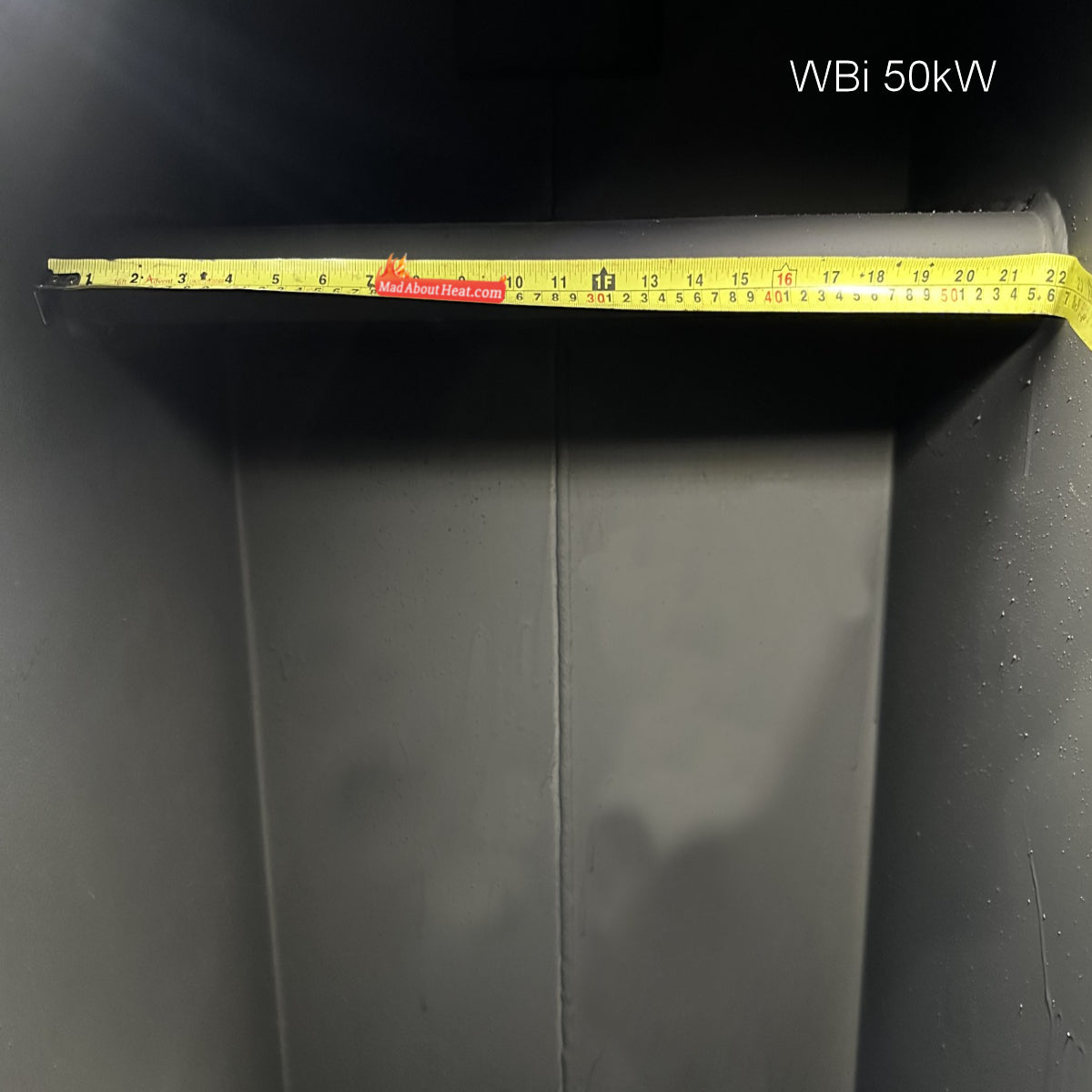

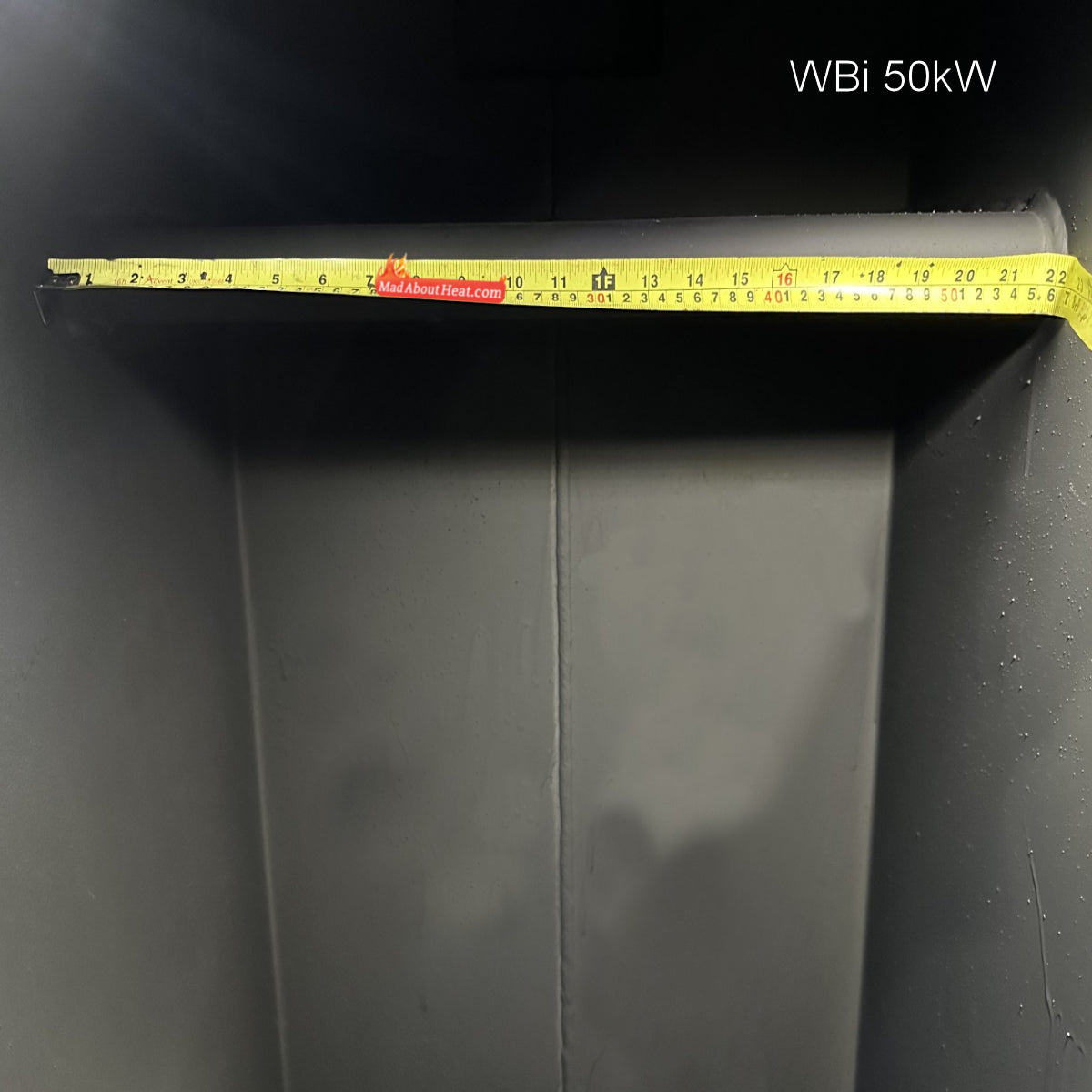

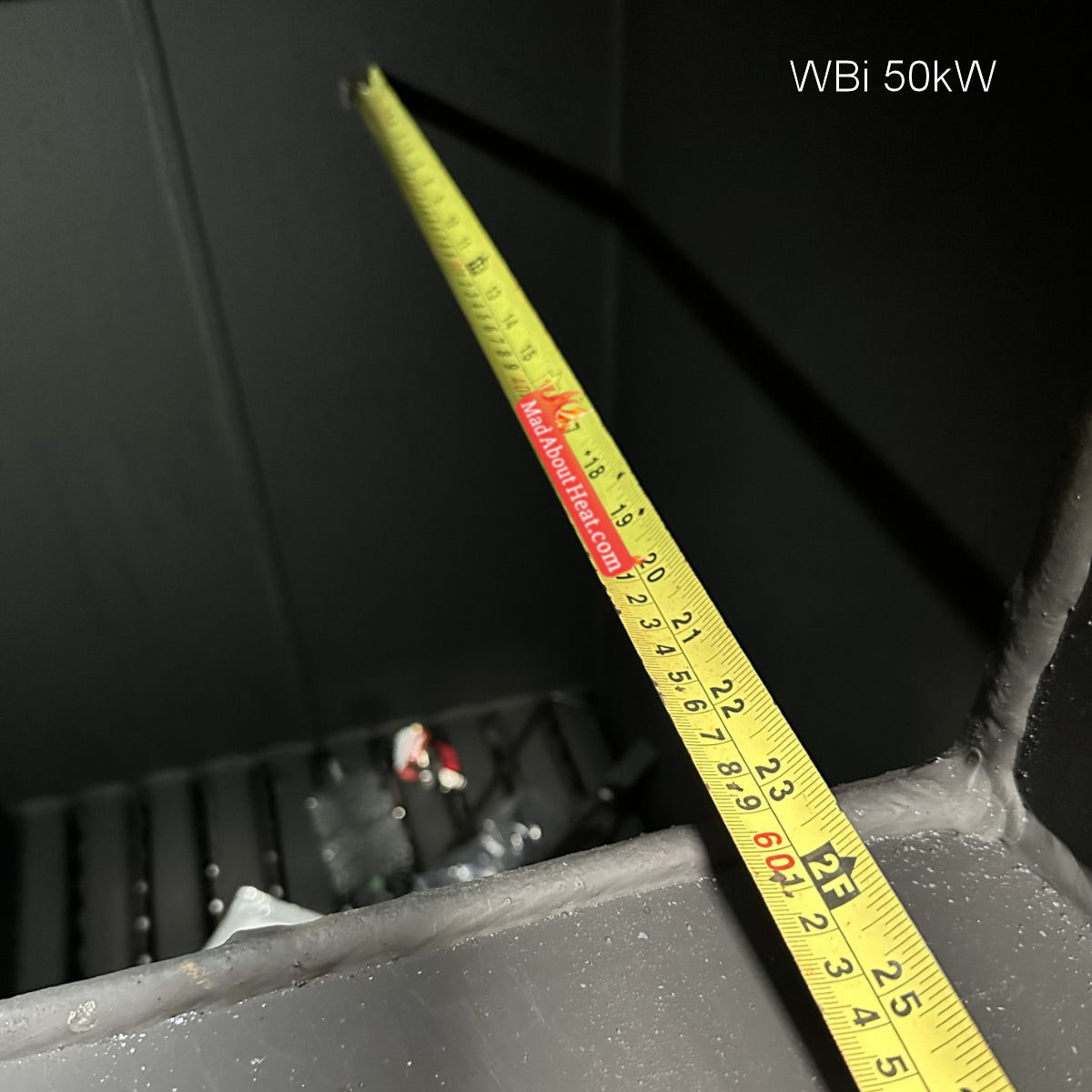

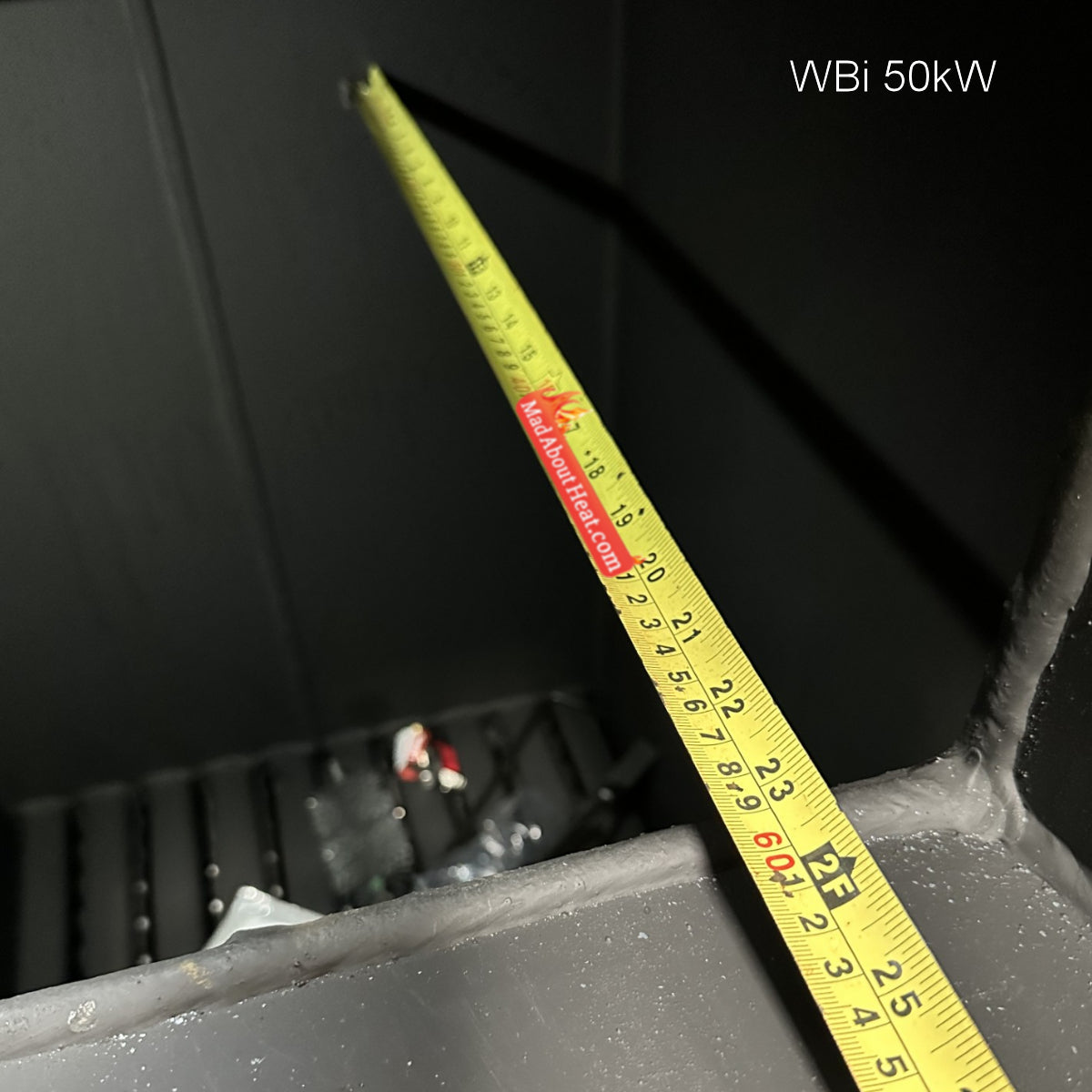

Combine this with class leading firebox sizes a refill times of around 10-14 hrs are achievable. For fire box sizes please see the spec chart as sizes vary with boiler outputs.

These log boilers can be used to burn wood, logs, timber, coal, peat, garden waste, light domestic waste and other combustible solid fuels.

The heat generated by burning fuel is used to heat up water circulating around the firebox, grate and exhaust channels heat exchanger, the water is then circulated around the central heating and hot water cylinder or buffer tank.

The WBI series multi fuel boilers have incinerator like characteristics, produce vast amounts of heat from burning solid fuels.

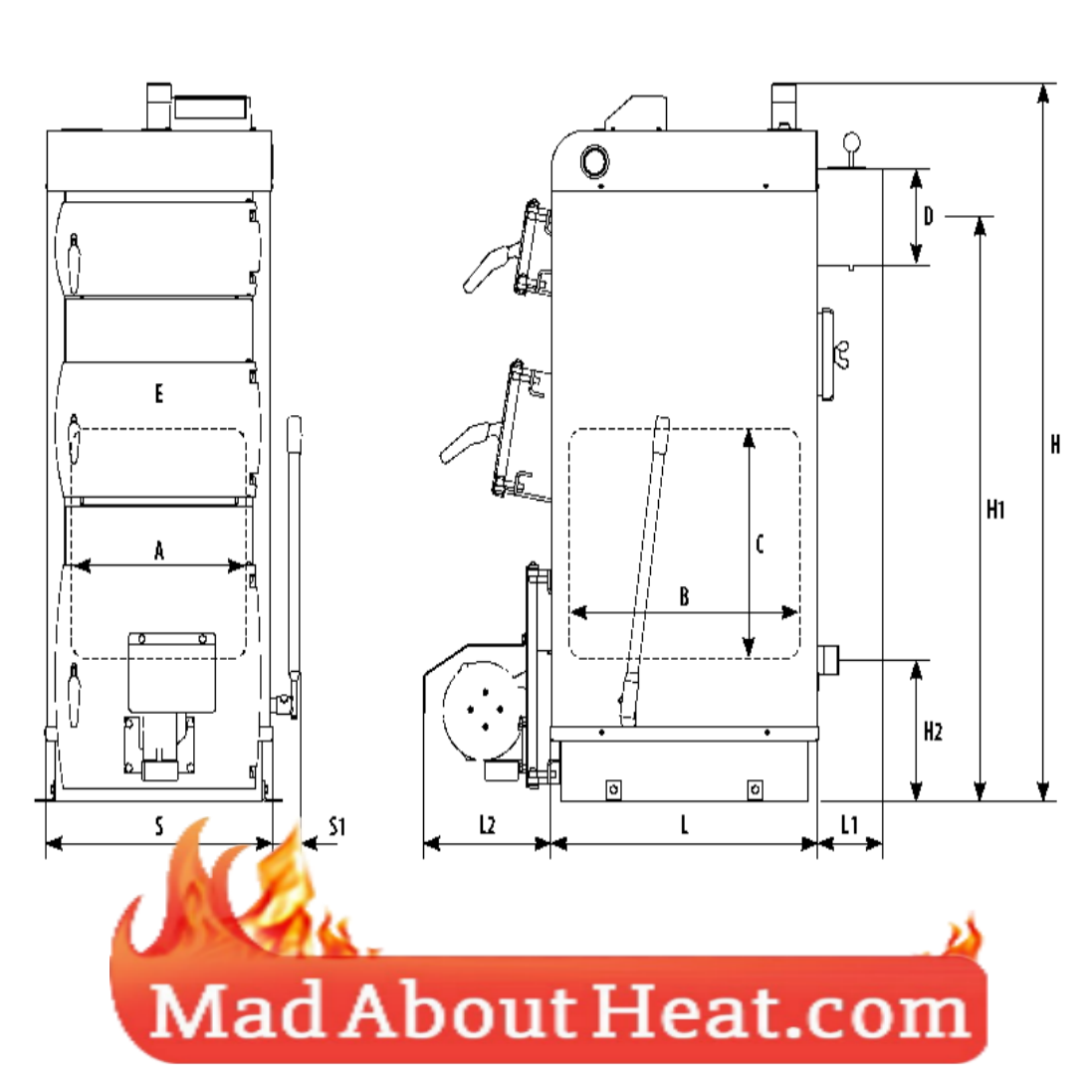

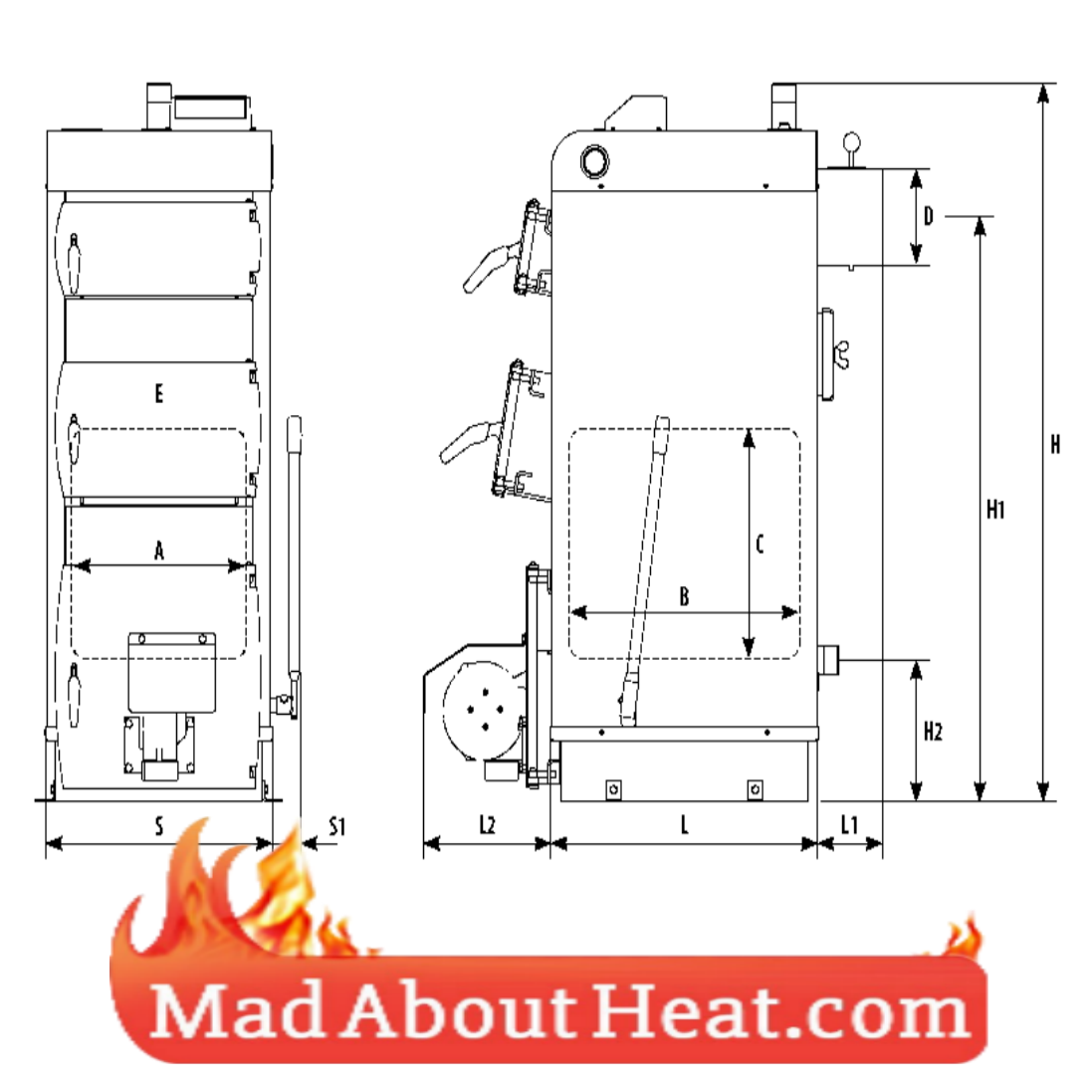

Taking a look at the machine itself:

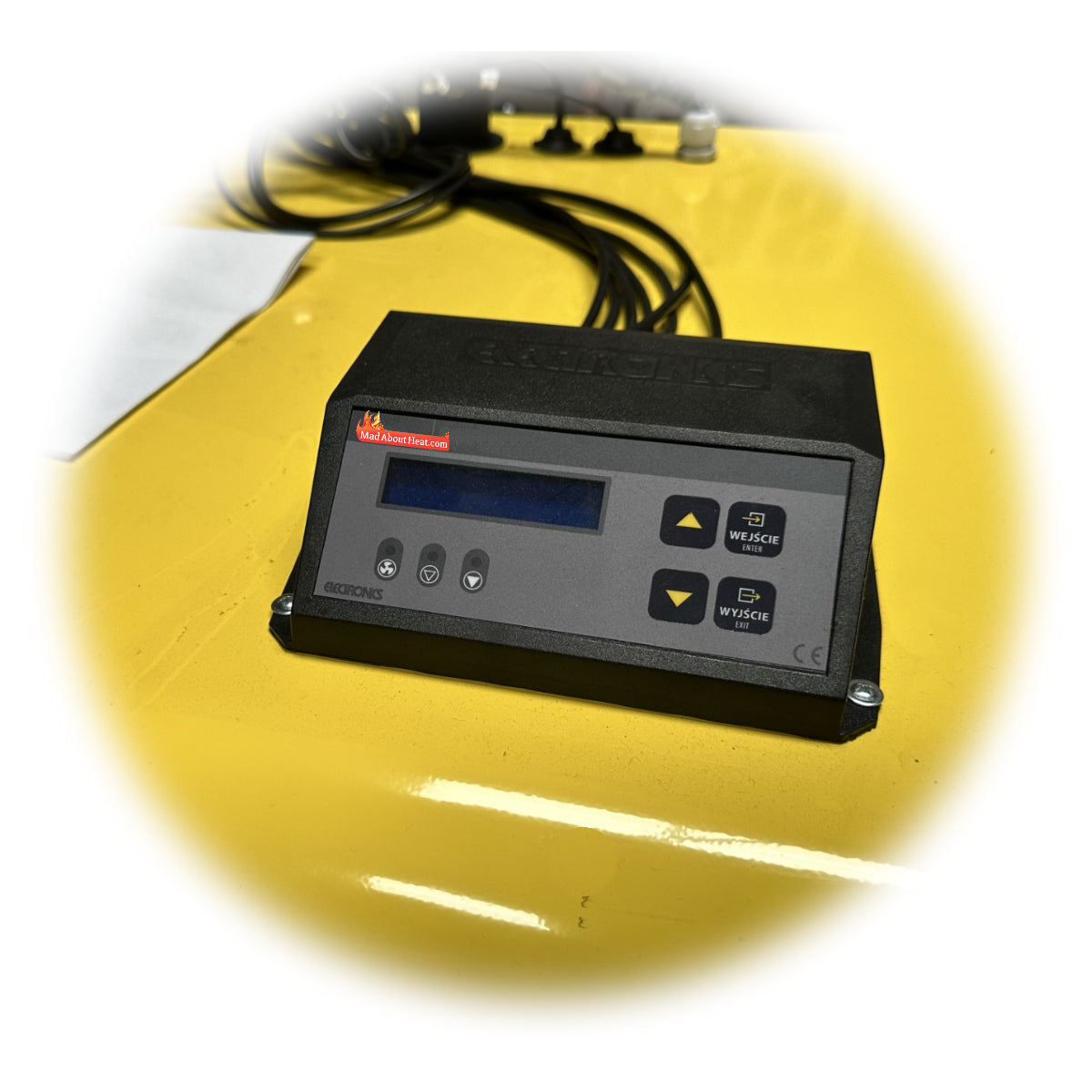

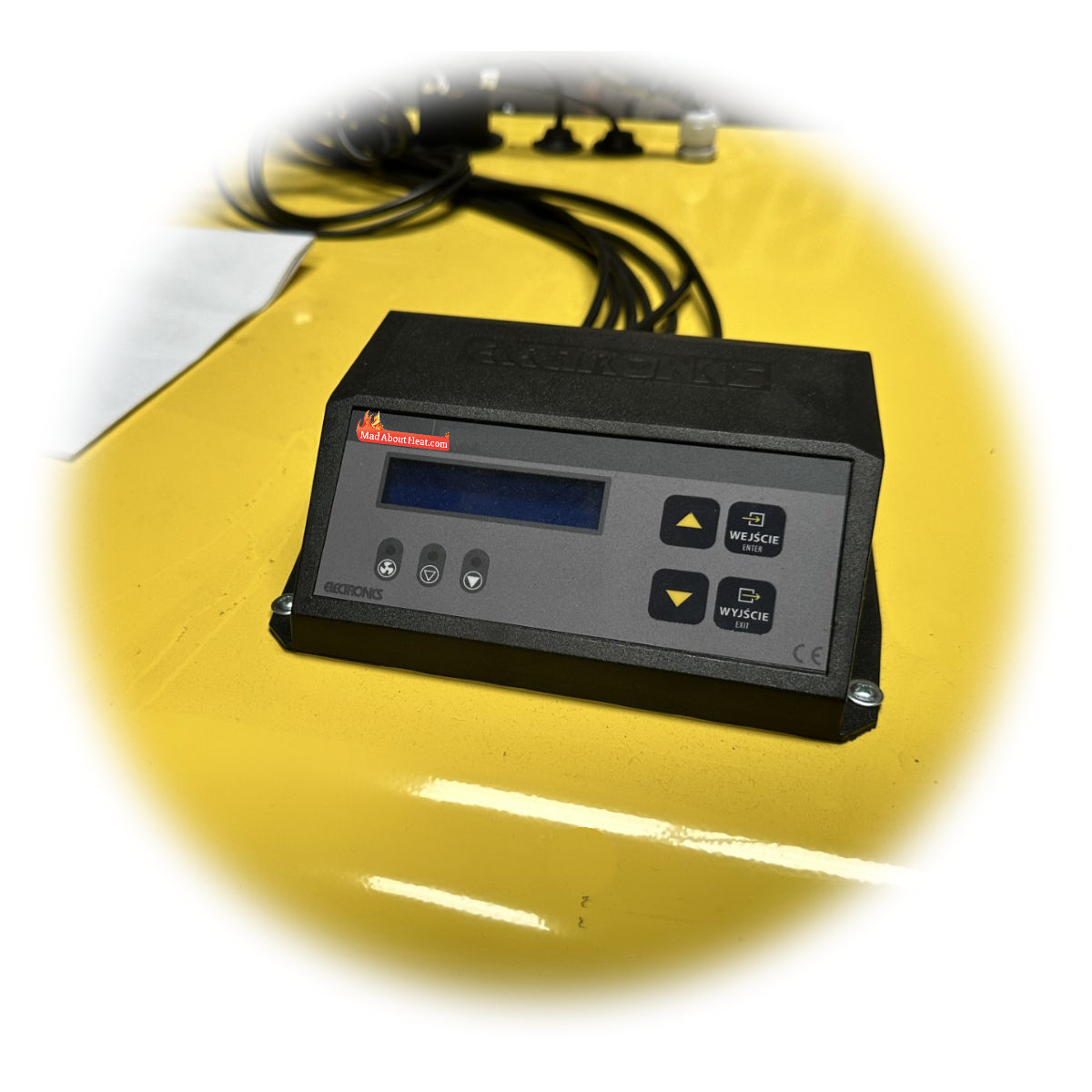

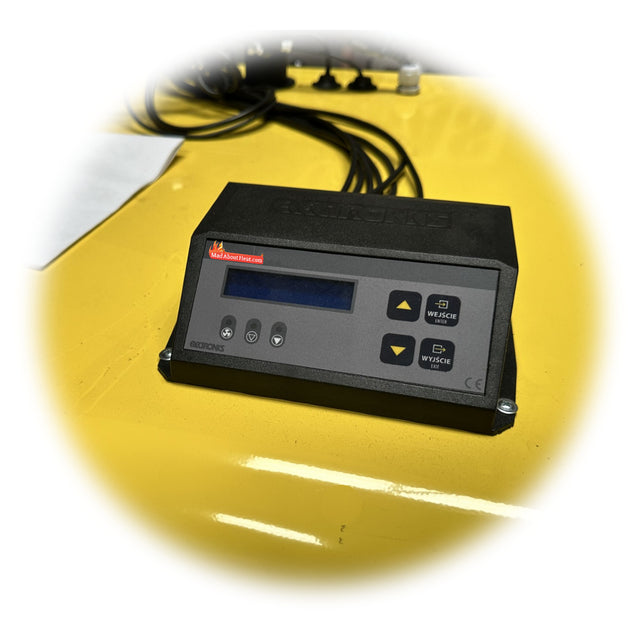

On top of this multi fuel burner is the controller. Equipped with latest intelligent algorithms, they require very little input once programmed, with the initial programming taking no more than 1 minute they can differentiate between various power demands to keep hot water supply temperature curve, flat.

Looking at the front, top opening has maintenance access for cleaning out the heat exchanger channels, cleaning equipment devices are included. This task takes 3-4 minutes every 3-6 weeks.

Middle door is used for loading of fuel.

Bottom door, gives access to lighting of fuel, cleaning and ash emptying. Ash emptying is typically every 1-3 weeks depending on the fuel.

The fumes exit through the opening at the rear with a further cleaning access panel located just below that.

Multiple pump control capability.

The WBI burning direction of fuel is from bottom up, but always light from top.

Our range of multi fuel boilers are not to be confused with inferior units made out of sheet metal. Our boilers are solid, well made, intelligently engineered and constructed out of 5-6 mm purpose made steel, then laser cut with their mass being in the region of between 300-550 kg.

Engineered to last!

Ideal for all central heating applications vented or pressurised sealed systems and burning of most solid fuels.

Relevant European approval.

In stock and available for immediate delivery!

As with the rest of our items this wood boiler is a 100 % European product.

If you have any questions regarding this or any other product, please get in touch. Details are on 'Contact us' page.

WBi Boilers Spec |

Unit |

Model |

||||||||||

9 |

12 |

16 |

18 |

20 |

24 |

30 |

35 |

40 |

50 |

|||

Dimensions |

A |

[mm] |

250 |

290 |

340 |

450 |

560 |

|||||

B |

[mm] |

290 |

320 |

390 |

420 |

490 |

570 |

|||||

C |

[mm] |

340 |

325 |

390 |

380 |

340 |

365 |

425 |

525 |

725 |

||

D |

[mm] |

127 |

∅ 159 |

∅ 178 |

∅ 219 |

|||||||

E |

[mm] |

248 × 173 |

298 × 198 |

348 × 248 |

||||||||

L |

[mm] |

400 |

425 |

495 |

525 |

595 |

675 |

|||||

L1 |

[mm] |

110 |

||||||||||

L2 |

[mm] |

255 |

||||||||||

H |

[mm] |

1080 |

1115 |

1200 |

1205 |

1265 |

1335 |

1435 |

1635 |

1685 |

||

H1 |

[mm] |

915 |

910 |

990 |

975 |

1035 |

1105 |

1205 |

1405 |

1435 |

||

H2 |

[mm] |

210 |

235 |

|||||||||

S |

[mm] |

370 |

390 |

440 |

550 |

660 |

||||||

S1 |

[mm] |

65 |

||||||||||

Primary fuel |

— |

Hard coal |

||||||||||

Thermal power* |

[kW] |

9 |

12 |

16 |

18 |

20 |

24 |

30 |

35 |

40 |

50 |

|

Area of heated rooms** |

[m²] |

≤ 100 |

≤ 140 |

≤ 180 |

≤ 200 |

≤ 220 |

≤ 260 |

≤ 320 |

≤ 370 |

≤ 420 |

≤ 530 |

|

Efficiency |

[%] |

80 - 90 |

||||||||||

Power control range |

[%] |

±2 |

||||||||||

Capacity of combustion chamber |

[dm³] |

20 |

27 |

33 |

33,5 |

45 |

53 |

80 |

110 |

150 |

210 |

|

Boiler water tank capacity |

[dm³] |

28 |

38 |

52 |

55 |

70 |

75 |

96 |

102 |

110 |

130 |

|

Heat exchanger material |

— |

Steel P265GH [PN-EN 10028]; thickness 6 mm |

||||||||||

Maximum working pressure |

[bar] |

2 |

||||||||||

Required min. chimney draught*** |

[Pa] |

20 |

23 |

25 |

28 |

35 |

||||||

Min./max. water temperature |

[°C] |

57/95 |

||||||||||

Weight of boiler without water |

[kg] |

148 |

181 |

202 |

214 |

248 |

253 |

320 |

352 |

382 |

520 |

|

Diameter of water connection |

[cal] |

G 1 1/2 |

||||||||||

Control |

— |

controller SP-16 LOGIC |

||||||||||

Additionally as a standard |

— |

set of cleaning tools |

||||||||||

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

WBi boiler, an overview.

Hover over + to see inside.